Chapter: Mechanical : Manufacturing Technology : Shaper, Milling and Gear Cutting Machines

Milling

Milling

Milling is a process of producing

flat and complex shapes with the use of multi-tooth cutting tool, which is

called a milling cutter and the cutting edges are called teeth. The axis of

rotation of the cutting tool is perpendicular to the direction of feed, either

parallel or perpendicular to the machined surface. The machine tool that traditionally

performs this operation is a milling machine. Milling is an interrupted cutting

operation: the teeth of the milling cutter enter and exit the work during each

revolution. This interrupted cutting action subjects the teeth to a cycle of

impact force and thermal shock on every rotation. The tool material and cutter

geometry must be designed to withstand these conditions. Cutting fluids are

essential for most milling operations. Three types of feed in milling can be

identified:

Feed per

tooth: the basic parameter in milling equivalent to the feed in turning.

Feed per tooth is selected with

regard to the surface finish and dim ensional accuracy required. Feeds per

tooth are i n the range of 0.05~0.5 mm/tooth, lower feeds are for finishing

cuts; feed per revolution: it

determines the amount of material cut per on e full revolution of the

milling cutter. Feed per revolution is calculated as fr = fz being the nu mber

of the cutter’s

teeth;

Feed per minute fm: Feed per minute is calculated taking into

account the rotational speed

N and

number of the cutter’s teeth z, fm = fzN = frN

Feed per minute is used to adjust the feed change gears.

Three types of feed in milling can be identified:

Feed per tooth fz: the basic pa rameter in milling equivalent

to the feed in t urning.

Feed per tooth is selected wit h

regard to the surface finish and dimensiona l accuracy required (see Section

5.10 Selection of Cutting Conditions). Feeds per tooth ar e in the range of

0.05~0.5 mm/tooth, lower feeds are for finishing cuts; feed per revoluti on fr:

it determines the amount of material cut pe r one full revolution of the

milling cutter. Fee d per revolution is calculated as

fr = fz ,z being the number of the cutter’s

teeth;

Feed per minute fm: Feed per

minute is calculated taking into account the rotational speed N and number of

the cutter’s tee th z, fm = fzN = fr,NFeed per minute is use d to

adjust the feed change gears. In down millin g, the cutting force is directed

into the work table, which allows thinner workparts tobe machined. Better

surface finish is obtained but the stress load on the teeth is abrupt, which

may da mage the cutter.In up milling, the cutting fo rce tend to lift the

workpiece. The work conditi ons for the cutter are more favourable. Because the

cutter does not start to cut when it makes contact (cutting at zero cut is

impossible), the surface has a natural waviness.

Milling Operations

Owing to the variety of shapes

possible and its high production rates, m illing is one of the most versatile

and widely used machining operations. The geometric form created by milling

fall into three major groups: P lane surfaces: the surface is linear in all thre

e dimensions. The simplest and most convenient type of surface;

Two-dimensional

surfaces: th e shape of the surface changes in the direc tion of two of the

axes and is linear along the third axis. Examples include cams;

Three-dimensional surfaces: the shape of the surface changes

in all three d irections.

Examples include die cavities, gas turbine blades, propellers,

casting patter ns, etc.

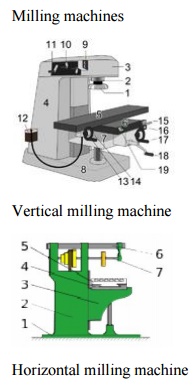

Milling

machines

Vertical

milling machine and

The conventional milling ma

chines provide a primary rotating motion fo r the cutter held in the spindle,

and a linear feed motion for the workpiece, which is fastened onto the

worktable. Milling machines for machin ing of complex shapes usually provide both

a rotating primary motion and a curvilinear fe ed motion for the cutter in the

spindle with a stationary workpiece. Various machine designs are available for

various milling operations. In this section we discuss only the most popular

ones, classified into the followin g types:

Column-and-knee milling ma chines; v Bed type milling

machines;

Machining

centers.

Column-and-knee milling ma chines

The column-and-knee millin g

machines are the basic machine tool for milling. The name comes from the fact

that this machine has two principal components, a column that supports the

spindle, and a knee that su pports the work table. There are two differen t

types of column-and-knee milling machines according to position of the spindle

axis:

horizontal, and vertical.

Milling cutters

Brazed cutters: Very limited

numbers of cutters (mainly face mills) are made with brazed carbide inserts.

This design is largely replaced by mechanically attached cuutters.

Mechanically

attached cutters: The vast majority of cutters are in this category. Carbide

inserts are either clamped or p in locked to the body of the milling cutter.

Classification of milling cutters may also be associated with

the various milling operations

Related Topics