Chapter: Environmental Biotechnology: Aerobes and Effluents

Membrane Bioreactors

Membrane Bioreactors

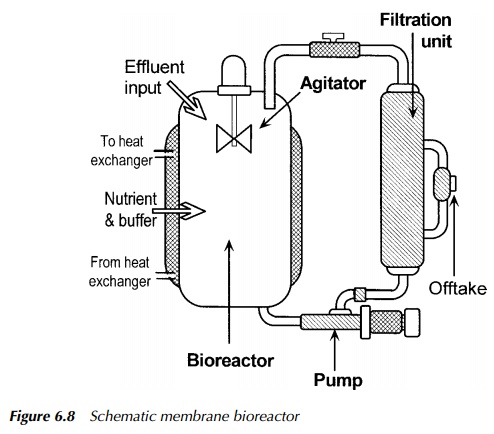

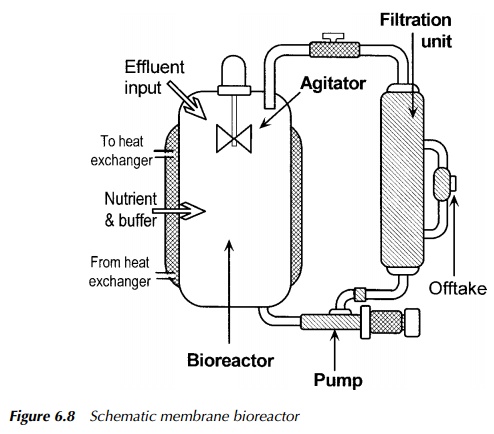

This system, instead of utilising conventional methods of gravity

settlement, achieves the desired biomass retention by means of a cross-flow

filtration process, as shown in Figure 6.8.

The development of effective

methods of micro- and ultra-filtration has opened up the potential for using

membrane bioreactor technology on various forms of domestic and industrial

effluents. There are three general types of reactor systems which have been

developed, namely solid/liquid separation, gas permeable and extractive

systems. The membrane element allows the passage of small molecules, but

retains the total resident microbial population. As a result, the cumulative

overall bioactivity and the resultant speed of remediation is boosted, since

not only are micro-organisms no longer lost with wash-out flow, but also,

conditions for even the slowest-growing member species of the microbial

community are able to be adequately enhanced. This is of particular relevance

to xenobiotics and the more recalcitrant components of wastewaters, as their

biological break-down is often brought about by bacteria which themselves have

a relatively long establishment period within the population. The high biomass

levels within the bioreactor itself obviously necessitate abundant readily

available oxygen, though the high organic loading and efficient intrasystem

microbial conservation com-bine to make the hydraulic retention time entirely

independent of the solids

Since the membrane allows gaseous transport while

constraining the biological phase, there is provision within the reactor for

bubbleless aeration and oxygenation consequently can take place over a

relatively large surface area, thereby improving the efficiency of this

process. In addition, the membrane itself may become an attachment zone for

biofilm formation.

Thus, the membrane

bioreactor can offer a greater degradation capacity for per-sistent chemicals,

making possible the biological removal of benzene, nitroben-zene,

dichloroaniline and polyaromatic hydrocarbons (PAHs), for example, which

represent a significant risk, both to the environment and human health, due to

their high toxicity. Removal efficiency for these substances can approach 99%.

The membrane bioreactor has

proved its suitability as an efficient system for degradation of recalcitrant

compounds and significantly higher biomass con-centrations and utilisation

rates are routinely achieved than in corresponding alternative treatment systems.

In common with most operational, rather than experimental, biological

detoxification processes, not all of the contaminants present in the effluent

are typically completely converted into carbon dioxide and water, a certain

percentage being turned into metabolic byproducts instead, though this can

amount to less than 5% in a well-managed bioreactor system. Part of this

involves the gradual and controlled introduction of novel wastewater elements,

to ensure that acclimatisation is maximised and any potential tendency for

‘shock loadings’ avoided. This is a clear example of the value of permitting

optimised microbial adaptation to the individual application.

These systems are, of

course, more expensive than the conventional activated sludge or trickling

filters, but produce a much smaller quantity of excess sludge for subsequent

disposal of treatment. In addition, they produce an elevated COD removal and

would seem particularly well suited to use in small-scale plants where the

production of high-quality final effluent is a priority.

Related Topics