Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Lime Mortar

Lime Mortar

Lime mortar is made by mixing

lime, sand and water. Lime used for mortar may be fat lime (quick or hydrated

lime) or hydraulic lime. Fat lime has high calcium oxide content. Its hardening

depends on loss of water and absorption of carbon dioxide from the atmosphere

and possible recrystallisation in due course. Hydraulic lime contains silica,

alumina and iron oxide in small quantities. When mixed with water it forms

putty or mortar having the property of setting and hardening under water.

Slaked fat lime is used to prepare mortar for

plastering, while hydraulic lime is used for masonry construction and are most

suitable for construction of chimneys and lightly loaded superstructure of

buildings. The mix proportions of lime mortar for various types of works are

given in Table 12.2.

Notes:1. Sand in lime

mortar is an adulterant, and reduces its shrinkage. Lime mortar becomes porous

allowing air to penetrate and helps the mortar in hardening.

2. Lime mortar is not suitable for water-logged

areas and damp situations.

Lime mortars have plasticity and

placability, good cohesion with other surfacings and little shrinkage. They

harden and develop strength very slowly continuously gaining strength over long

period. Fat lime mortars do not set but stiffen only as water is lost by

absorption (by masonry units) and evaporation. The gain in strength is a very

slow reaction of lime with carbon dioxide absorbed from air.

Preparation

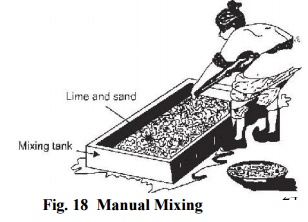

Manual Mixing Lime and sand in required quantities

are placed on an impervious floor or in a tank (Fig. 18). The constituents are

thoroughly mixed dry by turning them up and down with spades. Water is added

and mixing is done again with spades till mortar of uniform colour and

consistency is obtained.

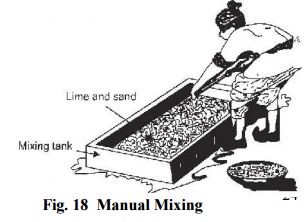

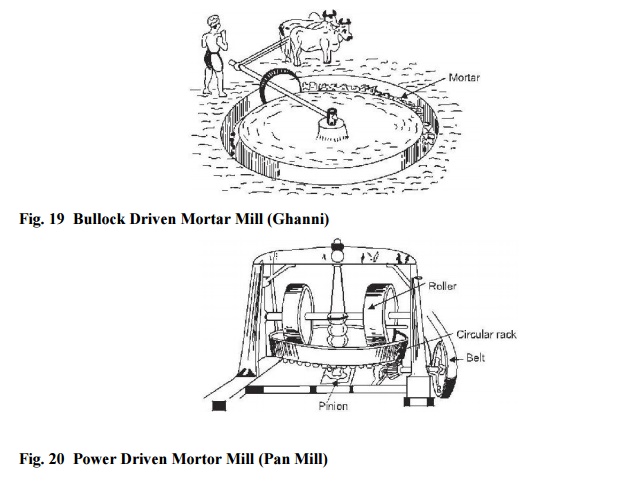

Mill Mixing Mills used for preparing lime mortars

in undeveloped countries may be a chakki or ghanni run by bullocks (Fig. 18)

while a pan mill (Fig. 19) is used in developed countries. In the case of

ghanni the required quantity of ingredients in the form of putty is put in the

trench and grinding for 100 to 200 revolutions is carried out by moving stone

roller. The operation takes about 2 to 3 hours for each batch of mix; the time

required in a Pan mill is much less.

Precautions Lime mortar or putty

should be kept moist till use and in no case its drying is allowed. The mortar

made of hydraulic lime should be consumed within one day and that with fat lime

within 2-3 days.

Related Topics