Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Lean Production and Agile Manufacturing

Lean Production

LEAN PRODUCTION

Lean

production is a term that embraces many of the topics that we have covered in

earlier chapters, topics such as flexible manufacturing, minimizing work in process,

"pull" systems of production control, and setup time reduction. The

term itself was coined by MIT researchers to describe the collection of

efficiency improvements that Toyota Motors undertook to survive in the Japanese

automobile business after World War II . Because of its

origins at Toyota Motors, the same collection of Improvements has also been

called the "Toyota production system'.

Historical Notes: The person given credit for initiating many of the methods of

lean production was Toyota chief engineer named Taiichi Ohno (l9121990). In the

post world War II period, the Japanese autornotive industry had to basically

start over. Ohno visited a U.S.auto plant to learn American production methods.

At that time, the car market in Japan was much smaller than in the U.S., so a

Japanese automotive plant could not afford the large production runs and huge

work in process inventories that we had here. (As it turns out. OUr plants

cannot afford them any longer cithcr.) Ohno knew that Toyota's plants needed to

be more flexible. Also, space was (and is) very precious in Japan. These

conditions. as well as Ohno's apparent aversion to waste in any furm (mllda, as

the Japanese call it). motivated him to develop some of the basic ideas and

procedures that have come \0 be known as lean production. Over the next several

decades. he and his colleagues perfected tbcsc ideas and procedures, which

included just in time production and the kanban system of

production control. smoothed production, setup time reduction, quality circles,

and dcdkated adherence to statistical quality control Ohno himself didnot

coin the term "lean production" to describe the collection

of actions taken at Toyota to improve production efficiency. In fact, he

titled his book, The Toyota Production System: Beyond Large Scale

Production. The term "lean production" was coined by

researchers at MIT to describe the activities and programs that seemed to

explain Toyota's success: the efficiency with which they produced cars and the

qua1ity of the cars they produced.

The MIT research project came to he known as the International

Motor Vehicle Program (IMVP). Included in the research was a survey of 87

automobile assembly plants throughout the world. The research was popularized

by the book The Machine that Changed the World. In the

subtitle of the book was the term "lean production"

Let us

provide two definitions of lean production. Our first definition is a

paraphrase of two of the authors of The

Machine that Changed the World. Womack and Jones define lean as doing "more and more with

less and less less human effort, less equipment, less time, and less space while coming closer and closer to providing

customers with exactly what they want". We are taking some liberties in

using this quote, It comes from their book titled Lean Thinking (p. 15), and they use these words to define

"lean thinking," which is lean production but expanded in scope to

include distribution and other functions beyond the factory.

The

second definition is developed to introduce our discussion of the principles of

lean production. Lean production can

he defined as an adaptation of mass production in which workers and work cells

are made more flexible and efficient by adopting

methods that reduce waste in all forms. According to another author of The Machine that Changed the World, lean production is based on four principles:

minimize waste

perfect firsttime

quality

flexible production

lines

continuous improvement

Let us

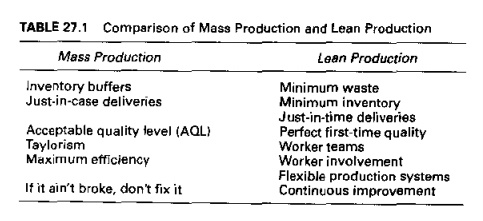

explain these principles and at the same time compare Jean production with its

predecessor, mass production. The comparison is summarized in Table 27.1.

Minimize Waste. All four principles

of lean production are derived from the first principle: minimize waste. 'Taiichi

Ohno's list of waste forms can be listed as follows:

(1)

production of defective parts, (2) production of more than till: number uf

items needed, (3) unnecessary inventories, (4) unnecessary processing steps,

(5) unnecessary movement of people, (6) unnecessary transport of materials, and

(7) workers waiting. The various procedures used in the Toyota plants were

developed to minimize these forms of waste. A number of these procedures have

been discussed in previous chapters. For example, lean principle 2 (perfect

first time quality), discussed next, is directed at eliminating production of

defective parts (waste form 1). The just in time production system (Section

26.7) was intended to produce no more than the minimum number of parts needed

at the next workstation (waste form 2). This reduced unnecessary inventories

(waste form 3). And so on, as we will see now.

Perfect

First Time Quality. In the area of quality, the comparison between mass production

and lean production provides a sharp contrast. In mass production, quality

control is defined in terms of an acceptable quality level or AQT. (Section 22.2.1). This means

that a certain level of fraction defects is sufficient, even satisfactory. In

lean production, by contrast, perfect quality is required. The just in time

delivery discipline (Section 26.7) used in lean production necessitates a zero

defects level in parts quality, because if the part delivered to the downstream

workstation is defective, production stops. There is minimum in

ventory in lean system to act as a buffer. In mass production, inventory buffers are

used just in case these quality problems occur. The defective work units are

simply taken off the line and replaced with acceptable units, However, the

prohlem is that such a policy tends to perpetuate the cause of the poor quality.

Therefore, defective parts continue to be produced. In lean production. a

single defect draws attention to the quality problem, forcing corrective action

and a permanent solution. Workers inspect

their own production. minimizing the delivery of defects to the downstream

production station

Flexible Production Systems. Mass

production is predicated largely on the principles of Frederick W. Taylor. one

of the leaders of the scientific management movement in the early

1901}s(Historical Note 2.1). According to Taylor, workers had to be told every

detail of their work methods and were incapable of planning their own tasks. By

comparison. Iean production makes use of worker teams to organize the tasks to

be accomplished and worker involvement to solve technical problems. One of the

findings reported in The Machine that Changed the World was that

workers in Japanese "lean production" plants received many more hours of training than their U.S, counterparts

(380 hours of training vs.46 hours. Another finding was the lower number of job

classifications in Japanese lean plants. The study showed an average of 11.9

job classifications in Japanese plants versus an average of 67.1 in L:.S.

plants. Fewer job classifications mean more cross training among workers and

greater flexibility in the work force

In mass

production, the goal is to maximize efficiency. This is achieved using long

production runs of identical parts. Long production runs tolerate long setup

changeovers, In lean production. procedures are designed to speed the

changeover. Reduced setup times allow for smaller batch sizes. thus providing

the production system with greater flexibility. Flexible production systems

were needed in Toyota's comeback period because of the much smaller car market

in Japan and the need to be as efficient as possible.

Continuous Improvement. In mass

production, there is a tendency to set up the operation, and ifitts working, leave it alone. Mass production

lives by the motto: “lf it ain't broke, don't fix it." By contrast. lean

production supports the policy of continuous improvement. Called kaizen by the Japanese, continuous

improvement means constantly searching for and implementing ways to reduce

cost, improve quality, and increase productivity. The scope of continuous

improvement goes beyond factory operations and involves design improvements as

well. Continuous improvement is carried out one project at a time. The projects

may be concerned with any of the following problem areas: cost reduction. quality

improvement, productivity improvement, setup time reduction, cycle time

reduction, manufacturing lead time and working process inventory reduction, and

improvement of product design to increase performance and customer appeal. The

procedure for carrying out a continuous improvement project in the quality area

is outlined in Section 21.4.2, Similar procedures can be applied to other

problem areas.

Related Topics