Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rails

Kraut Kramer Multi Probe Rail Testing Trolley

Kraut Kramer Multi Probe Rail Testing Trolley

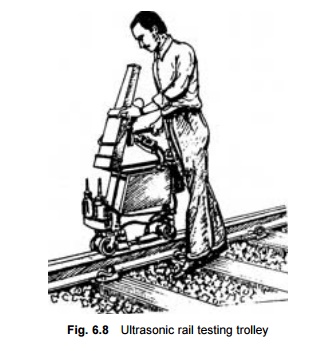

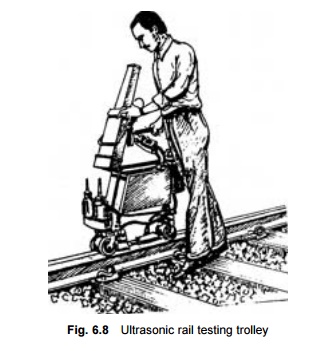

This is the most common type of equipment used on Indian Railways for detecting flaws in the rail Fig. 6.8. The equipment is fitted on a hand trolley that is carried on the rails. There are two probes: a normal probe and an angle probe, both act independently. The probe material used for the production of ultrasonic waves is barium titanate, which produces and transmits vertical ultrasonic waves of four megacycles frequency through the vertical probe and 2 mega cycles frequency through the angle probe. The cylindrical probe is mounted on a knuckle jointed holder frame and has a renewable bakelite wear plate at the base. As the probe is worked over the rail, the bakelite piece takes the wear completely. The height of the probe above the rail surface can be adjusted in the holder assembly. The normal probe is powerful enough to scan the entire rail depth for defects. It can detect longitudinal discontinuities in the head at the junction of either the web and the foot or the web and the head as well as cracks from bolt holes. It cannot, however, detect vertical cracks. The defects detected by the normal probe are represented on the oscilloscope screen in the form of firm echoes protruding from a base line. Ordinarily, two echoes are visible on the screen, the initial echo due to the partial reflection of the waves from the rail top and the back echo from the bottom of the rail. Any echo between the initial and the back echo with a corresponding reduction in the height of the back echo is termed a flaw echo and is indicative of a flaw. The position of the flaw can be known by reading the distance of this intermediate echo from the initial echo, which will be the distance of the flaw from the rail top.

The ultrasonic rail testing trolley can be used without any block protection, but one has to be vigilant about the movement of trains. Progress depends upon the experience and the efficiency of the operator. The work is quite strenuous in nature and a single operator cannot observe the screen continuously for a long time. Work can also not be done during the middle of the day in the summer months because the operator will not be able to pick up the signals clearly. On account of these limitations, the work progresses rather slowly and approximately 2-3 km of rail are covered per day with two operators.

Related Topics