Chapter: Environmental Biotechnology: Contaminated Land and Bioremediation

In situ techniques

In situ techniques

The fundamental basis of in situ engineered bioremediation involves introducing oxygen and nutrients to the contaminated area by various methods, all of which ultimately work by modifying conditions within the soil or groundwater. There are three major techniques commonly employed, namely biosparging, bioventing and injection recovery. In many respects, these systems represent extreme ver-sions of a fundamentally unified technology, perhaps best viewed as individual applications of a treatment spectrum as will, hopefully, become clearer from the descriptions of each which follow.

As set out previously, the major benefits of in situ methods are their low intrusion, which enables existing buildings and site features to remain undis-turbed, their relative speed of commencement and the reduced risk of contami-nation spread.

Biosparging

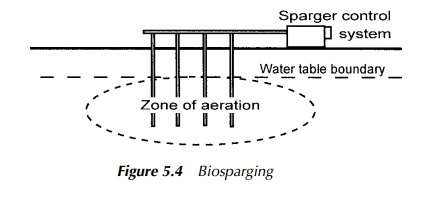

Biosparging is a technique used to remediate contamination at, or below, the water table boundary, a generalised diagram of which appears in Figure 5.4.

In effect, the process involves superaeration of the groundwater, thereby stimulating accelerated contaminant biodegradation. Though the primary focus of the opera-tion is the saturated zone, the permeability of the overlying soil has a bearing on the process, since increased oxygenation of this stratum inevitably benefits the overall efficiency of remediation.

Air is introduced via pipes sunk down into the contaminated area and forms bubbles in the groundwater. The extra oxygen made available in this way dis-solves into the water, also increasing the aeration of the overlying soil, stimulating the activity of resident microbes, which leads to a speeding up of their natural ability to metabolise the polluting substances. The method of delivery can range from relatively simple to the more complicated, dependent on individual require-ments. One of the major advantages of this is that the required equipment is fairly standard and readily available, which tends to keep installation costs down. Typ-ically the sparger control system consists of a pressure gauge and relief valve to vent excess air pressure, with associated flow meters and filter systems to clean particulates from the input. More sophisticated versions can also include data loggers, telemetry equipment and remote control systems, to allow for more pre-cise process management. It should be obvious that extensive and comprehensive site investigation, concentrating on site geology and hydrogeology in particular, is absolutely essential before any work starts.

Bioventing

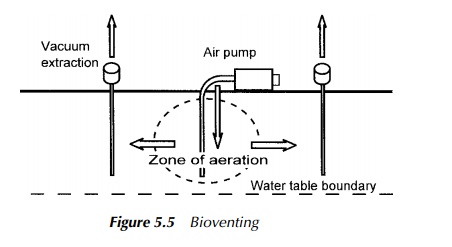

Bioventing is a technique used to remediate contamination above the water table boundary, and again a generalised diagram appears in Figure 5.5. This process also involves superaeration, again with the intention of stimulating accelerated breakdown of the pollutants present, though this time it is taking place within the soil itself, instead of the groundwater. Bioventing is not generally suitable for remediating sites with a water table within one metre of the surface, nor for heavy or waterlogged soils, since air flow is compromised under these conditions.

Air is introduced from a compressor pump, via a central pipe, or set of pipes, dependent on the size of the area to be treated, down into the region of contamination. The extra oxygen availability thus achieved, as in the previous approach described, stimulates the resident microbes, which then treat

The air flow through the soil is further driven by vacuum extractors peripheral to the treatment zone, which increases the dissolved oxygen levels of the soil water and thus facilitates uptake by the native micro-organisms. Volatile compounds, which are either present as part of the original contamination, or generated as byproducts of the biological treatment, are often mobilised during processing and thus more easily extracted. However, in many practical applications, the air extraction rate is adjusted to maximise decomposi-tion underground, thus reducing a separate requirement for surface treatment of volatile compounds.

As with the biosparger, control devices typically regulate the pressure, fil-ters clean particles from the intake and the flow rate is monitored in operation, with data loggers and telemetry systems again featuring in the more complex applications.

Unsurprisingly, bioventing also requires extensive and comprehensive site investigation before commencement, not least because the proper positioning of the necessary system of pipework is essential to the proper functioning of this technique.

Injection recovery

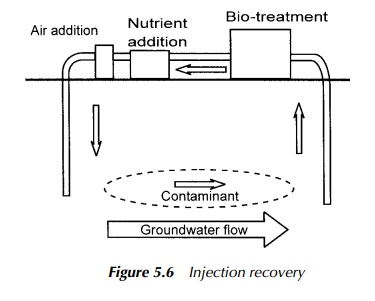

The injection and recovery method, for which a generalised diagram appears in Figure 5.6, makes use of the movement of groundwater through the zone of contamination to assist the remediation process. Although, as mentioned in the introductory comments, this approach shares many functional similarities with the preceding technologies, it is essentially more sophisticated and refined, with the biological treatment being effectively divided into two complementary stages. Thus, what may be considered a ‘virtual’ bioreactor is established within the soil matrix, with the actual clean-up activity taking place both within the groundwater and also externally to it.

The major characteristic of this technique is the two-well system sunk into the ground, the ‘injection well’ and the ‘recovery well’, the former being located

‘upstream’ of the latter. Nutrients and air are forced down the injection well, and as they flow through the contamination, they stimulate the growth and activity of the indigenous micro-organisms, which begin the process of remediation.

Groundwater, now rich in contaminant, microbes, microbial metabolites and contaminant breakdown products is extracted via the ‘recovery well’ from beyond the contaminated zone. It then undergoes additional biological treatment above ground in an associated bioreactor vessel, frequently where it is subjected to highly aerobic conditions, before being reinjected, having been further replenished with air and nutrients. This cycle may be repeated many times in the course of treatment. Process control is achieved by having separated out the aeration, nutrient addition and biotreatment phases into isolated near-episodic events and the facility for direct analysis of the abstracted water enables treatment progress to be monitored with much greater certainty. As a consequence, the injection recovery method neatly overcomes many of the traditional criticisms of in situ treatment techniques, particularly in respect of difficulties in ensuring true optimisation of conditions and determining the end-point.

Of course, this technique does not avoid the necessity for thorough site investigation and geological surveys, since it is clearly imperative that the particulars of the subterranean water flow, soil depth and underlying geology are known in considerable detail.

Related Topics