Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Important Questions and Answers: Total Quality Management Tools and Techniques

1. What is meant by benchmarking?

The process of gathering

information about the ŌĆśbest quality product

manufacturing company ŌĆś in order to copy , follow and

excel, is known as benchmarking.

Benchmarking is defined as a

systematic method (or) popular TQM tool by which organizations can measure

themselves against the best industry practices.

2. What is meant by quality function deployment

(QFD)?

Quality function deployment (QFD)

is a TQM tool which ensures that customerŌĆÖs

requirements are met throughout the design process and also in the production

systems.

3. Write about House of quality.

The primary planning tool in QFD

is the House of Quality. House of Quality is a set of matrix used to translate

the voice of the customers into technical design requirement that meet specific

target values and characteristics of the final product. Because of its

structure, it is referred to as the ŌĆśHouse of

QualityŌĆÖ.

4. Name

different loss measurements in TPM?

a. Down time

losses ŌĆō Planned ŌĆō

Unplanned

b. Reduced

Speed Losses

c. Poor

Quality Losses

5. What is

meant by Failure Mode and Effect Analysis (FMEA) ?

Failure Mode and Effect Analysis

(FMEA) is an analytical technique which combines the technology and experience

of the people

To identify foreseeable failure modes of a product(or) process

To plan for its elimination.

6. Define Reliability.

Reliability is defined as the

probability of a product performing satisfactorily without failure of a

specified function under specified conditions for a specified period of time.

7. What is Debug failure ?

Debug includes a high failure

rate at the initial stages because of inappropriate use (or) flaws in the

design (or) manufacturing.

8. What are

the two important types of FMEA ?

1. Design

FMEA

2. Process

FMEA

9. What are

the three classes of customer needs?

1. Dissatisfiers:

are the needs that are expected in a product (or) service

2. Satisfiers:

are needs that customers say they want

3. Exciters/Delighters:

are new (or) innovative features that customer do not except.

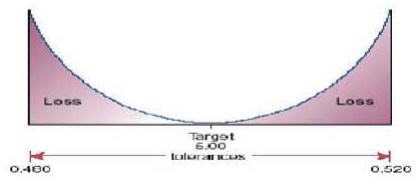

10. Draw the Taguchi Loss

Function?

11. What are the three types of benchmarking?

1. Internal

benchmarking

2. Competitive

benchmarking

3. Process

benchmarking.

12.

Name different types of matrix diagrams.

1. L- Matrix

2. T- Matrix

3. Y- Matrix

4. X- Matrix

5. C-

Matrix.

13.

What is meant by performance efficiency?

Reduced speed losses are measured by tracking

performance efficiency using the Performance efficiency E=(C*N/T)*100

Where

C=Cycle time

N= Number

of units produced.

14. What are the three main categories of failure?

1. Debug

2. Chance

3. Wear out

15.

What are the six steps in benchmarking

process?

ŌĆó

Deciding what to benchmark

ŌĆó

Understanding current performance

ŌĆó

Planning

ŌĆó

Studying others

ŌĆó

Learning from the data

ŌĆó

Using the findings and taking action

Related Topics