Chapter: Aquaculture Principles and Practices: Harvesting and Post-Harvest Technology

Harvesting methods in Aquaculture

Harvesting methods

Methods of harvesting naturally depend on the culture system, the species cultured and the form in which the product is to be marketed. Properly designed fish ponds have special provisions for draining and easy harvesting, whereas in pens and similar enclosures suitable nets and other fishing devices have to be used. In open-water stocking and ranching, fishing equipment used in capture fisheries is the common choice. Harvesting is usually the most labour-intensive operation in an aquaculture farm, apart from its construction, so there have been attempts to introduce as much mechanization as possible in order to reduce labour.

Harvesting drainable ponds

Harvesting from drainable ponds is relatively easy, if there is a harvesting sump or similar device. In a nursery or fry-rearing pond it is almost essential to have a harvesting sump to avoid injury to fry or fingerlings during harvest. Drainage is performed at a rate suited to the size of the outlet and the drainage channels, and the fish are concentrated in the harvesting sump. From the harvesting sump, the fish can be collected by loading equipment, if necessary with the help of a net. In case the harvesting sump is considered too small for the quantity of fish, it may be necessary to combine seining and draining to harvest the fish in good condition. Some of the fish may be seined and the rest caught in the sump. When live fish are marketed, it is useful to spray fresh water or aerate the water in the sump, to avoid weakening or mortality of the fish.

In Asian brackish-water ponds, where special catching ponds or canals are provided, fish are concentrated in the catching areas by taking advantage of their habit of swimming against currents. At high tide, tidal water is allowed to flow into the pond system through the catching ponds (see fig. 6.7) and by opening the sluice gates the fish are allowed to swim from the rearing ponds to the catching ponds. From there they can easily be fished out, when the tide turns, after full or partial drainage.

In shrimp ponds in Asia, long bag nets are set in the sluice gates to catch the shrimps as they swim out from the pond with the outflow of water at low tide (see fig. 6.10). The high tide stimulates them to move around the pond and when the tide changes they move with the current and are caught in the nets.The best time for such total harvest is during the new moon or full moon periods, as at this time the shrimps are more active. But at the full moon, many of the shrimps may be moulting and the soft-shell shrimps caught will not fetch a good price in the market. Catches are best at night and a light placed over the sluice gate will serve to lure shrimps to swim towards it.

Some species of shrimps, such as Penaeusmonodon, do not swim out of the pond easilyand repeated draining is necessary in order to harvest a good percentage of the stock. Another method of harvest is by concentrating them in peripheral canals in the pond by partial draining, and then seining them from the canals.

Seining undrainable ponds

The so-called undrainable fresh-water or brackish-water ponds require pumping to

drain. For economic reasons they are drained only very occasionally, if at all. In such cases, and when multiple harvesting and stocking are practised, it is necessary to resort to fishing with commercial fishing gear. The most common fishing equipment for pond farms is a seine net. It is well suited for harvesting most species of fish, although some species like tilapia (e.g. Tilapia aurea) and certain strains of commoncarp can escape the nets by burrowing into the bottom mud. Species like mullets, milkfish and silver carp can escape by jumping the net.

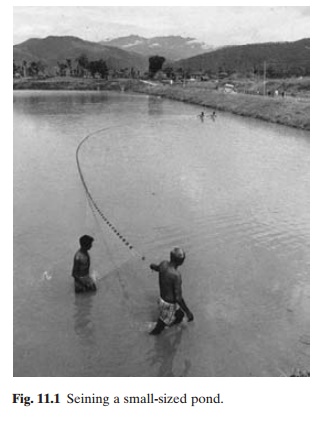

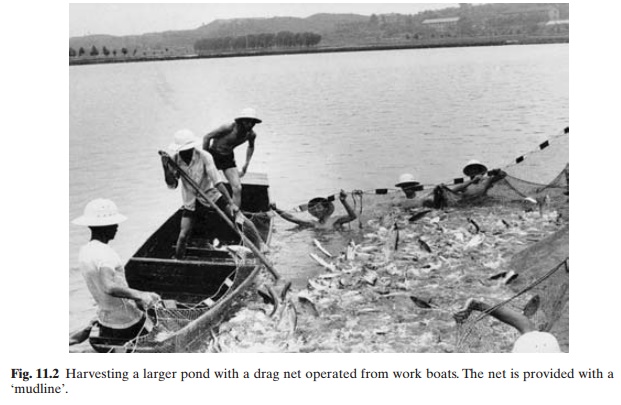

When harvesting is to be done by seining, the shape and size of ponds in farms are designed with this in mind. Usually the length of a seine net is about one and a half times the width of the pond and the depth about two to three times the pond depth. A preferred and economic length is not more than about 150m. The mesh size of the net depends on the size of the animal to be harvested. Too small a mesh will make dragging the seine more difficult due to increased resistance in water and so a larger mesh size is preferred when the size of the animal permits it. In nursery ponds smaller-meshed seines, even ones made of mosquito nets, are used but then the smaller pond dimensions enable easy fishing. Generally, wooden brail poles are attached to both ends of the seine for convenience in pulling and keeping the net stretched vertically (fig. 11.1). The poles can be used for attaching hauling lines, when mechanized equipment is used. The head line has floats made of cork, styrofoam or other suitable floating material and the lead line has lead sinkers or lead cores. Traditional lead lines have a tendency to sink into muddy bottoms and allow the net to roll up, resulting in loss of animals caught in the net. To avoid this, the use of ‘mud lines’ is recommended. They consist of a number of relatively thin ropes tied loosely together, made of a material (such as jute or cotton) that readily absorbs water. Mud lines skid on the bottom, without digging or lifting the mud. This reduces escape under the seine (fig. 11.2). Hepher and Pruginin (1981) described the use of a bunch of synthetic strings, bound together to form a thick band for attachment to the bottom line of seines, to prevent the line from sinking into the mud. They reported that a similar result can be obtained when polyethylene strips of about

20cm width and 40cm length are attached to the bottom line. The strips should be folded over the line so that they stretch about 20cm behind the line. To prevent the escape of fish that jump over the net, the head line is propped up using large floats.

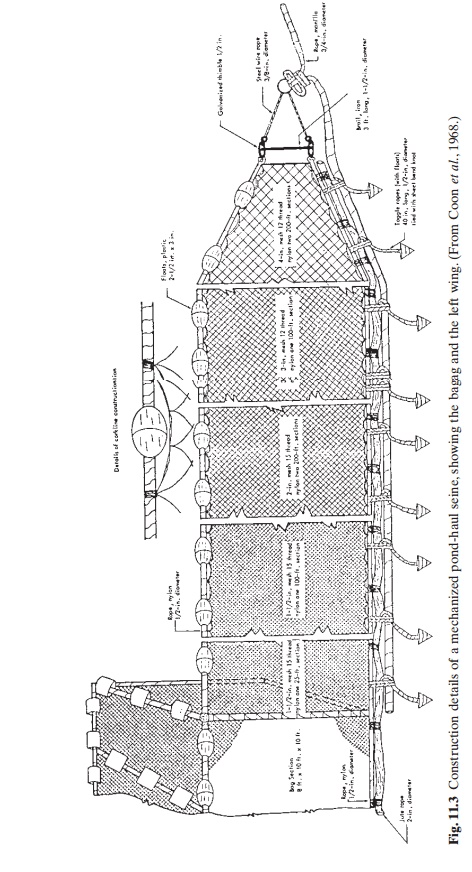

When dragged, the seine bows out creating a shallow bag for the catch.To increase the capacity, the central part of the seine can be made deeper so that it forms a deeper sack during operation. To increase the capacity further, and reduce escape, the seines can be equipped with special bags. Coon et al. (1968) described a mechanized haul seine system (fig. 11.3) which consists of two wings and a bag. The wings are composed of six sections of various length and mesh sizes. Large-sized meshes are used in the leading wing sections to reduce resistance to drag. The sections are joined together by shackles or cordage. Perpendicular breast lines at the ends of the adjoining sections are laced together. Bridles and brails attached to the edge of each wing keep the seine wings open vertically and are also used for attaching the

hauling lines. Jute rope, which soaks up water, is attached to the bottom line of the wings and the bag and it keeps the bottom line down without digging into the mud during operation. The bag section has the same small mesh size as the adjoining sections of the wings.

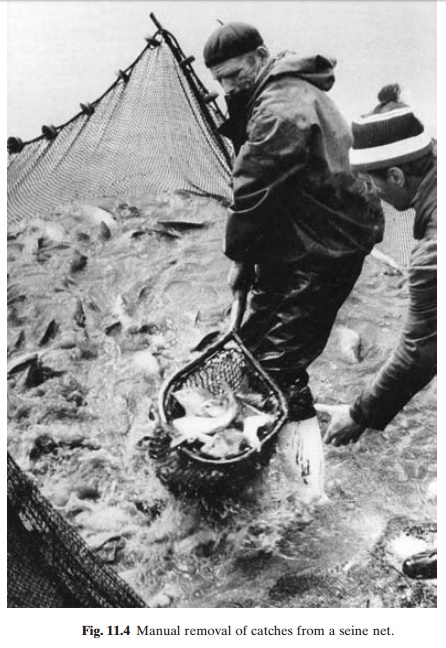

The type of seine proposed by Coon et al. needs a pontoon-type barge for carrying and setting it, and a mechanical seine puller for hauling the net. In smaller ponds seining is generally done manually (see fig. 11.1). The water level is reduced by partial drainage to concentrate the animals, making their capture easier. Seining generally starts at the deeper end of the pond and ends at the shallow part. Dragging the net without allowing it to rise requires skill and an experienced crew. It is better to use trucks or tractors for hauling when large nets are operated. Special winches can be fitted to the vehicles for this purpose. After reaching the shallow end of the pond, the net has to be closed in and raised to the embankment with the catch (see fig. 11.2). It is comparatively easy when the seines have detachable bags, as in the mechanized seines described by Coon et al. In unmechanized seines, considerable labour is involved if the catch is substantial (fig. 11.4), so different types of lifting devices have been developed. Mechanized dip nets are commonly used in large farms, but need two or three men to operate them. Another device used is a mechanized bucket elevator, but it can be installed only on a well-built concrete structure.

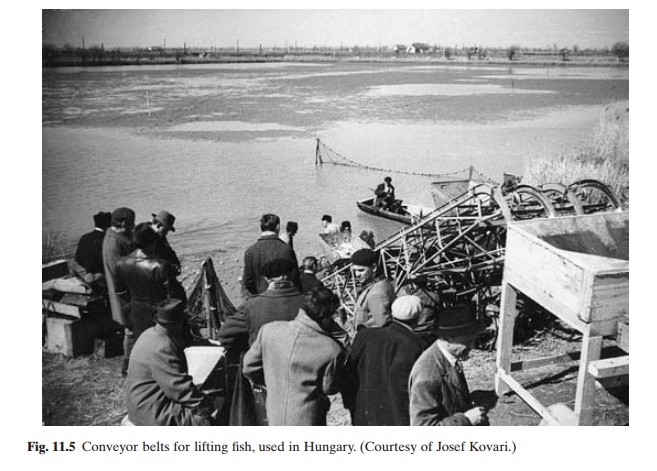

Purpose-built conveyor belts, similar to ordinary grain conveyors but with soft rubber belts and covers, are efficient to use, especially when the fish have to be lifted to a high elevation (fig. 11.5).The lower hopper of the belts can be filled by hand, by mechanized dip nets or by air-lift pumps. In order to avoid any injuries to the fish and to improve product quality, specially designed fish screws for lifting fish with water have been devised. The internal spiral ribbon and the pipe housing that revolve together lift up water along with the fish, in the space between the two. Different types of centrifugal fish pumps used in marine fishing have been tried in fish farms, but because of the damage to harvested fish they are not very widely used. Special air-lift pumps can lift the fish without

Other methods of fishing

As mentioned earlier, the habits of certain species like the milkfish and mullets of swimming against currents is made use of in harvesting them. Even in farms without any special catching ponds, as in old traditional Indonesian tambaks, it is fairly easy to concentrate the fish near the sluice gates at high tides, from where they can be caught by means of cast nets. In large ponds, a number of fishermen may have to be employed. The main disadvantage of this type of fishing is that a large number of fish are damaged and lose scales during removal from the net. Dip nets can also be used, even though they may not be so efficient. In milkfish ponds in Taiwan, gill nets are used for harvesting.

Several pieces of netting, each of length 30m and height about 1.6m are joined together and towed across the pond. Before harvesting, the fish are scared in order to empty their stomachs. This is achieved by dragging a scareline (a rope strung with a number of bamboo pieces) or by striking the water with bamboo poles from a raft or boat. Fish with empty stomachs normally reach the markets in a better condition.

In the traditional valli culture in lagoons in Italy and other Mediterranean countries, the special trapping devices called lavorieri serve the purpose of partial or sometimes even complete harvesting. Originally they consisted of screens made of reeds, installed in such a way as to lead fish into a terminal trapping chamber.

In modern vallis, aluminium or other metallic screens and traps are built on concrete barrages at the inlet. Fish swim against the current at high tide and are caught in the traps. Gill nets and seines are also used for fishing from the lagoon proper.

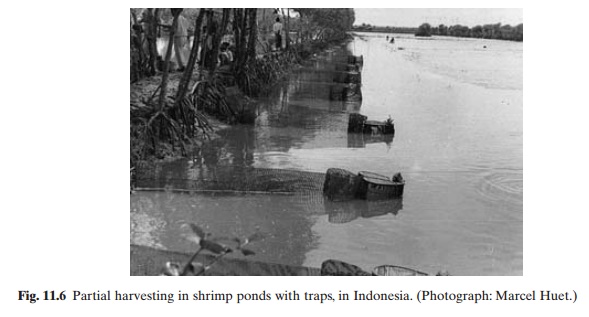

For partial harvesting of shrimp ponds, barrier traps made of bamboo screens are used in Southeast Asia, but they have the disadvantage that many of them do not have a bottom screen, which makes removal of the shrimp from the trap inconvenient. Also it is rather difficult to adjust the size of the mouth opening. Fyke-type shrimp traps with builtin bottoms that can be easily handled for removing shrimps are much more efficient (fig. 11.6). The mesh size of the trap, or the distance between bamboo slats (if made of bamboo), should be such that small shrimps can escape. The mouth of the trap should be adequately protected to prevent crabs from entering the trap. If operated at night with a lamp hung above to attract the shrimps, appreciable catches can be obtained. If the catches are heavy it is necessary to empty the trap periodically. Besides traps, cast nets, lift nets and seines can also be used for partial harvesting, in conjunction with lure lights at night.

In shrimp farms in Japan, harvesting is often done with pound nets. Each net consists of three or more conical net bags set in a semicircle, with a net fence set at a right angle to the shore. The bag nets are laced together with side nets. Shrimps swim along the fence into the pond and get caught in the bag nets. Hand-held electric equipment is reported to be used for harvesting shrimp in Taiwan (ASEAN, 1978) (see fig. 24.15). It consists of an accumulator and two bamboo poles. One of the poles is equipped with a metal tip and the other has a steel ring with a net attached. The metal tip is connected by wires to the anode of the accumulator and the steel ring to the cathode. The accumulator is carried in a backpack or on a small raft and the operator holds one pole in each hand as he wades through the ponds. When the gear is switched on, an electric field is formed between the two poles. The shrimps jump when exposed to the electric stimulation and are caught in the net. Total harvesting of large shrimp ponds is said to be achieved by this method in Taiwan.

In multiple stocking and harvesting systems, the ponds will contain different sized groups of animals and therefore special care has to be taken to return to the pond any undersized ones caught in the net. The selection of an appropriate mesh size goes a long way towards preventing the capture of undersized animals.

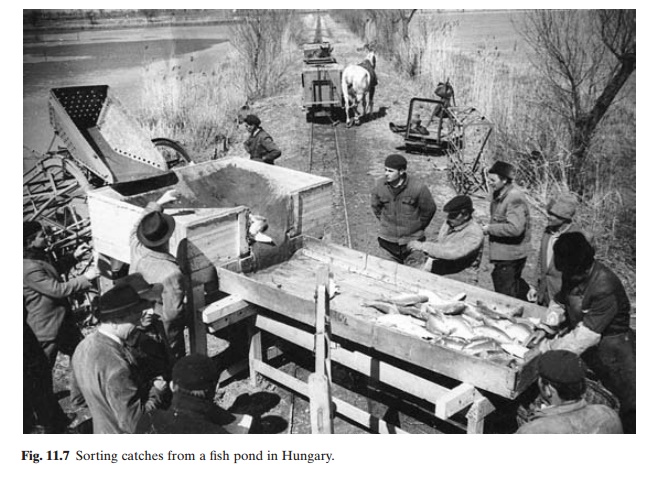

It may, however, be necessary to perform additional sorting (fig. 11.7). Besides hand sorting, special floating graders can be used, which are usually made of wooden or metal slats set at appropriate distances apart to retain animals above a certain size and allow smaller individuals to fall through.

Harvesting cage and raceway farms

It is comparatively easy to harvest stocks from intensive culture systems, particularly tank and raceway farms. They can easily be drained partially or completely as required and the animals removed by dip nets or suitable mesh.

Harvesting from cage farms can be a little more complex, depending on the location and size of the cages. Except in the case of small cages, it will not be practical or advisable to lift them for removing the stock. In many cases it may be possible to tow the cages to the shore and harvest the stock using dip nets. Where this is not feasible, boats may have to be used. When the farm has central or peripheral walk-ways, it is easier to raise the cages and remove the animals. But even then, some producers prefer to use seines to gather the fish and, in large farms, pumps may be used to transfer the fish to the loading area. In salmonid cage farms in Norway, feeding is stopped for a period of about a week before harvesting. This is done to empty the alimentary canal, so as to prevent quick deterioration and also to ‘firm up’ the flesh. During harvest the fish are removed very carefully to avoid bruising the skin and meat.

Special care is taken to avoid undue stress to the fish during harvest, as meat quality is known to be affected by stress. Generally, the fish are transported by live-hauling boats or in plastic tanks installed in boats or trucks.

Harvesting of molluscs

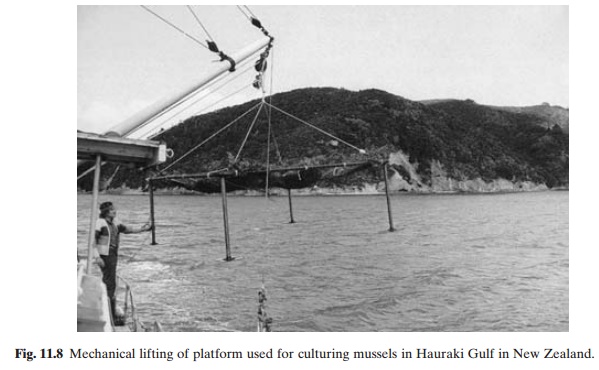

Methods of harvesting molluscs like oysters, mussels, etc., for market depend on the culture systems employed. In bottom culture, where the sea bed is planted with spat for on-growing, the most common harvesting method is dredging. From intertidal areas which are fully or partly drained at low tide, oysters or other molluscs can be easily collected by hand. But, as will be described, off-bottom methods of culture are commonly practised in modern oyster and mussel farms. The oysters and mussels are grown on sticks planted in the intertidal areas or hung on long lines, special nylon bags or plastic containers. In such cases, harvesting is relatively simple and can be done by hand or from a boat when necessary. When they are grown on special platforms, as for example mussels in New Zealand (fig. 11.8), mechanical lifting devices installed on a large boat may become necessary.

In countries like France, where there is a special market for greened oysters, fully grown flat or Portuguese oysters may be reared in small, shallow coastal ponds known as claires for up to six months in order to increase their weight and develop the green coloration. Claires are drained, dried and then fertilized before filling with salt water to a depth of about 25cm. Water is exchanged at spring tides. Oysters are stocked in these ponds at a high density. They grow in weight rapidly (almost doubling in a six-month period) and the bluish-green diatoms (Navicula), which grow in the claires, impart a green colour to the meat. Such large greened oysters fetch a high price in French markets.

When molluscs are dredged out from sea beds, some of the sand and silt swirled up during the operations may enter their mantle cavity. In such cases, the animals can be spread out on a cleansing plot or basin and covered with gently flowing sea water for varying periods of time. This helps them to eliminate any silt or sand and also recover from the fishing stress. They are transported alive to distant markets.

Related Topics