Chapter: Mechanical : Manufacturing Technology : Metal Joining Process

Gas welding

GAS WELDING

Sound weld is obtained by selecting proper size of flame, filler material and method of

moving torch

The temperature generated during the process is 33000c.

When the metal is fused, oxygen from the atmosphere and the torch combines with molten metal and forms oxides, results defective weld

Fluxes are added to the welded metal to remove oxides

Common fluxes used are made of sodium, potassium. Lithium and borax. Flux can be applied as paste, powder, liquid. solid coating or gas.

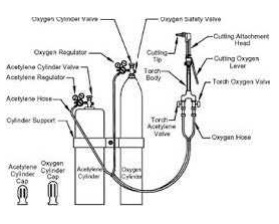

1GAS WELDING EQUIPMENT

1. Gas Cylinders Pressure

Oxygen – 125 kg/cm2 Acetylene – 16 kg/cm2

2. Regulators

Working pressure of oxygen 1 kg/cm2 Working pressure of acetylene 0.15 kg/cm2

Working pressure varies depends upon the thickness of the work pieces welded.

3. Pressure Gauges

4. Hoses

5. Welding torch

6. Check valve

7. Non return valve

2FLAMES PRODUCED DURING GAS WELDING

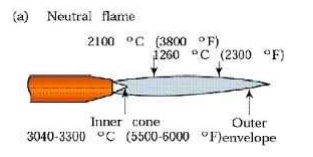

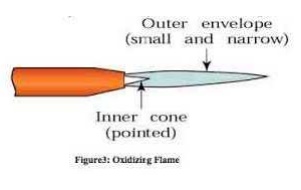

Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations:

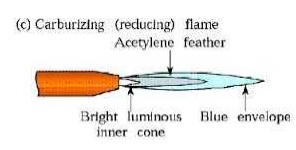

(a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing flame.

Addition of more oxygen give a bright whitish cone surrounded by the transparent

blue envelope is called Neutral flame (It has a balance of fuel gas and oxygen) (32000c)

• Used for welding steels, aluminium, copper and cast iron

oxygen give a bright whitish cone surrounded by the transparent

blue envelope is called Neutral flame (It has a balance of fuel gas and oxygen) (32000c)

• Used for welding steels, Aluminium, copper and cast iron.

Oxygen is turned on, flame immediately changes into a long white inner area (Feather)

surrounded by a transparent blue envelope is called Carburizing flame (30000c)

Advantages of Gas welding.

1.Simple Equipment 2.Portable 3.Inexpensive

4.Easy for maintenance and repair

Disadvantages Of Gas welding

1.Limited power Density 2.Very low welding speed.

3.High total heat input per unit length 4.Large Heat affected Zone

5.Severe Distortion

6.Not recommended for welding reactive metals such as titanium and Zirconium.

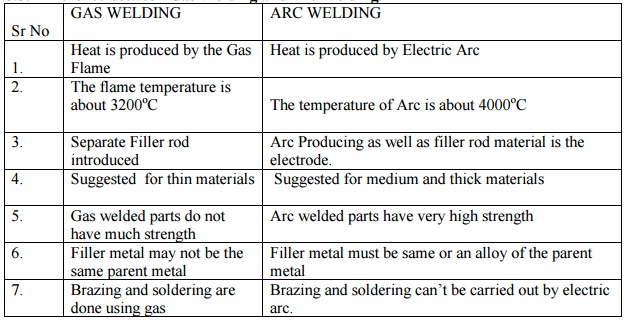

Difference between Gas Welding and Arc Welding

GAS WELDING

1. Heat is produced by the Gas Flame

2. The Flame temperature is about 3200oC

3. Separate Filler rod introduced

4. Suggested for thin materials

5. Gas welded parts do not have much strength

6. Filler metal may not be the same parent metal

7. Brazing and soldering are done using gas

ARC WELDING

1. Heat is produced by Electric Arc

2. The temperature of Arc is about 4000oC

3. Arc Producing as well as filler rod material is the electrode.

4. Suggested for medium and thick materials

5. Arc welded parts have very high strength

6. Filler metal must be same or an alloy of the parent metal

7. Brazing and soldering can’t be carried out by electric arc.

Related Topics