Chapter: civil : Applied Hydraulic Engineering: Turbines

Francis Turbine

Francis

Turbine

The Francis turbine is a type of

water turbine that was developed by James B. Francis in Lowell, MA. It is an

inward-flow reaction turbine that combines radial and axial flow concepts.

Francis turbines are the most common

water turbine in use today. They operate in a head range of ten meters to

several hundred meters and are primarily used for electrical power production.

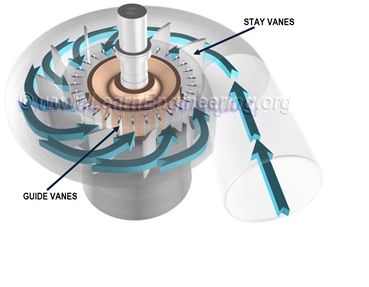

. The inlet is spiral shaped. Guide vanes direct the

water tangentially to the turbine wheel, known as a runner. This radial flow

acts on the runner's vanes, causing the runner to spi n. The guide vanes (or

wicket gate) may be adjustable to allow efficient turbine operation for a range

of water flow conditions.

As the water moves through the runner,

its spinning radius decreases, further acting on the runner. For an analogy,

imagine swinging a ball on a string around in a circle; if the string is pulled

short, the ball spins faster due to the conservation of angular momentum. This

property, in addition to the water's pressure, helps Francis and other

inward-flow turbines harness water energy efficiently. Water wheels have been

used historically to power mills of all types, but they are inefficient.

Nineteenth-century efficiency

improvements of water turbines allowed them to compete with steam engines

(wherever water was available).

In 1826

Benoit Fourneyron developed a high efficiency (80%) outward-flow

water turbine. Water was

directed tangentially through the turbine runner, causing it to

spin. Jean - Victor Poncelet designed an inward-flow turbine in about 1820 that

used the same principles. S. In 1848 James B. Francis, while working as head engineer

of the Locks and Canals company in the

water-powered factory city

of Lowell, Massachusetts,

improved on these designs to

create a turbine with 90% efficiency. He applied scientific principles and

testing methods to produce a very efficient turbine design. More importantly,

his mathematical

and graphical

calculation methods improved turbine design and engineering. His analytical

methods allowed confident design of high efficiency turbines to exactly match a

site's flow conditions.

The Francis turbine is

a reaction turbine, which means that the working fluid changes pressure as it

moves through the turbine, giving up its energy. A casement is needed to

contain the water flow. The turbine is located between the high-pressure water

source and the low-pressure water exit, usually at the base of a dam.

The inlet is spiral

shaped. Guide vanes direct the water tangentially to the turbine wheel, known

as a runner. This radial flow acts on the runner's vanes, causing the runner to

spin. The guide vanes (or wicket gate) may be adjustable to allow efficient

turbine operation for a range of water flow conditions.

As the water moves

through the runner, its spinning radius decreases, further acting on the

runner. For an analogy, imagine swinging a ball on a string around in a circle;

if the string is pulled short, the ball spins faster due to the conservation of

angular momentum. This property, in addition to the water's pressure, helps

Francis and other inward-flow turbines harness water energy efficiently.

Related Topics