Chapter: Electric Energy Generation and Utilisation and Conservation : Solar Radiation and Solar Energy Collectors

Flat Plate Collectors: Principle, Components, Types

FLAT PLATE COLLECTORS

The flat plate collectors forms the heat of any solar energy collection system designed for operation in the low temperature range, from ambient to 60 or the medium temperature, form ambient to 100. A well engineered flat plate collector is delivers heat at a relatively low cost for a long duration. The flat plat collectors is basically a heat exchanger which transfer the radiant energy of the incident sunlight to the sensible heat of a working fluid-liquid or air. The term ŌĆśflat plateŌĆÖ is slightly misleading in the sense that the surface may not be truly flat-it may be combination of flat, grooved or of other shapes as the absorbing surface, with some kind of heat removal device like tubes or channels. Flat plate collectors is used to convert at much solar radiation as possible into heat at the highest attainable temperature with the lowest possible investment in material and labour.

Flat plate collector have the following advantage over other types of solar energy collectors:

(i) Absorb direct, diffuse and reflected components o solar radiation,

(ii) Are fixed in tilt and orientation and thus, there is no needed of tracking the Sun,

(iii) Are easy to make and are low in cost,

(iv) Have comparatively low maintenance cost and Long lie, and

(v) Operate at comparatively high efficiency.

Principle of Flat Plate Collector

The principal behind a flat collector is simple. If a metal sheet is exposed to solar radiation, the temperature will rise until the rate at which energy is received is equal to the rate at which heat is lost from the plate; this temperature is termed as the ŌĆśequilibriumŌĆÖ temperature. If the back of the plate is protected by a heat insulting material, and the exposed surface of the plate is painted black and is coved by one or two glass sheets, then the equilibrium temperature will be much higher than that for the simple exposed sheet. This plate may be covered into a heat collector by adding a water circulating system, either by making it hollow or by soldering metal pipes to the surface, and transferring the heated liquid to a tank for storage. For heat with withdrawal from the system the equilibrium temperature must decrease, since no useful heat can be extracted at he maximum equilibrium temperature at which the collection efficiency is zero. The other extreme condition is when the flow of liquid is so flat that the temperature rise is very small; in such a case although the losses are small and the efficiency of the heat collection approaches 100 percent, yet no useful heat can be extracted. The optimum is approximately midway between the equilibrium temperature, whereby an output of hot liquid at a useful temperature is obtained.

Components of Liquid flat Plate Collector

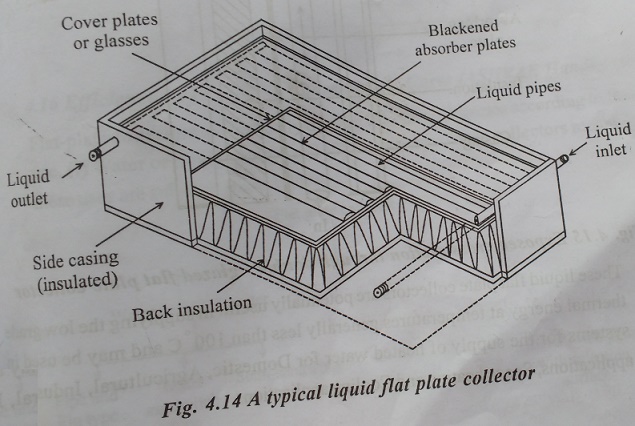

A flat collector (Fig 4.14) usually consists of the following components:

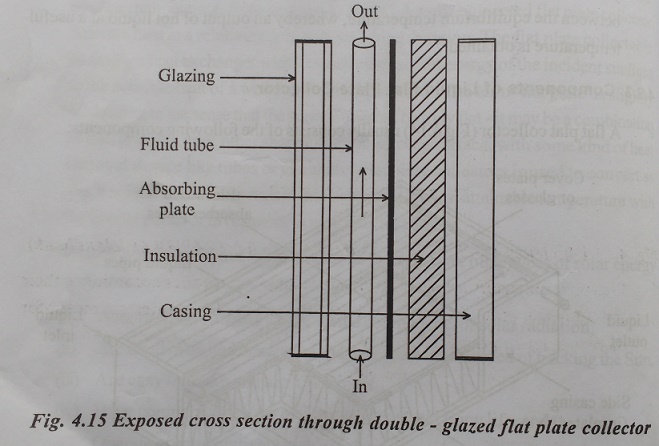

(i) Glazing, which may be one or more sheets of glass or other diathermanous (radiation transmitting) material(Fig.4.15).

(ii) Tubes, fins or passages for conducting or directing the heat transfer fluid from the inlet to the outlet.

(iii) Abserver plate which may be flat, corrugated or grooved with tubes, fins or passages attached to it.

(iv) Header or manifolds, to admit and discharge the fluid.

(v) Insulation which minimizes heat loss from the back and sides of the collector.

(vi) Container or casing which surrounds the various components and protects them from dust, moisture etc.

These liquid flat plate collectors are potentially useful in supplying the low grade thermal energy at temperature generally less than 100oC and may be used in system for the supply of heated water for Domestic, Agricultural, Industrial applications, Space heating and Cooling application.

Types of flat-Plate collectors

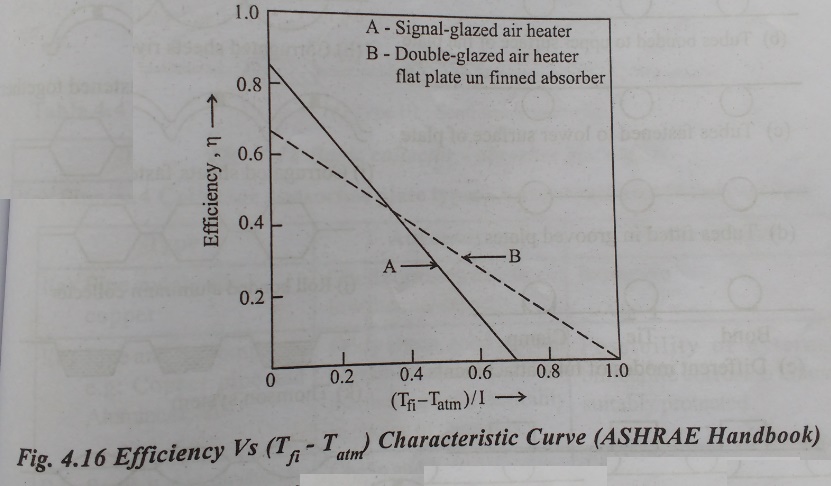

In flat plate collectors, the heat loss by convection is more important in the determination of their performance. The convective heat loss may be decreased by using double glazing, but the radiation reaching the absorber is reduced due to double reflection. Hence, at low temperature where this loss is small, use of single glazing gives a better efficiency than the double one while at higher temperature difference the use of glazing is advisable for better performance. Fig.4.16 Compares the efficiencies of single and double glazing flat plate collector in different temperature ranges.

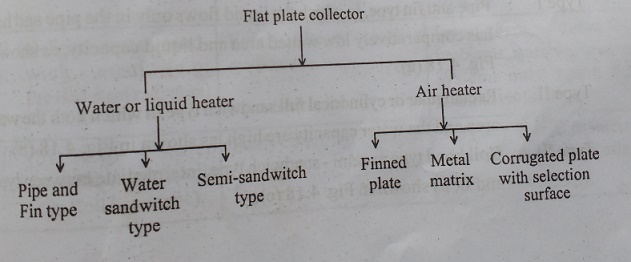

Flat-plate collectors are basically divided into two categories according to their use, (i) Water or liquid heaters and (ii) Air heaters and (ii) Air heaters. These collectors meant for these uses are sub-divided as follows:

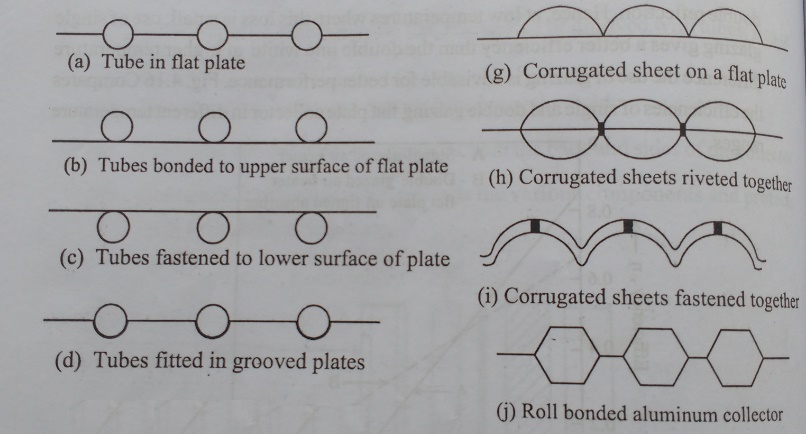

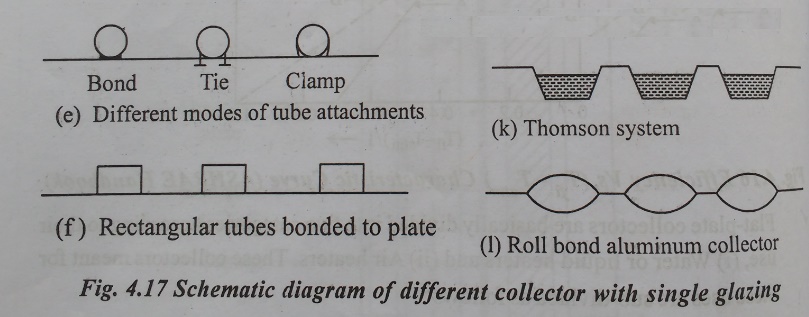

The schematic diagram of all these collectors, with single glazing are shown in Fig. 4.17. These absorber plates can be broadly classified into three basic types as shown in Fig.4.18, depending on the extent of wetted surface area relative to the absorbing surface area.

Type I : Pipe and in type, in which flows only in the pipe and hence has comparatively low wetted area and liquid capacity, as shown in ig.4.18(a).

Type II : Rectangular or cylindrical full sandwich type in which both the wetted area and the water capacity are high, as shown in Fig.4.18(b).

Type III : Roll bond type or semi-sandwich type, intermediate between types I and II, as shown in Fig.4.18(c).

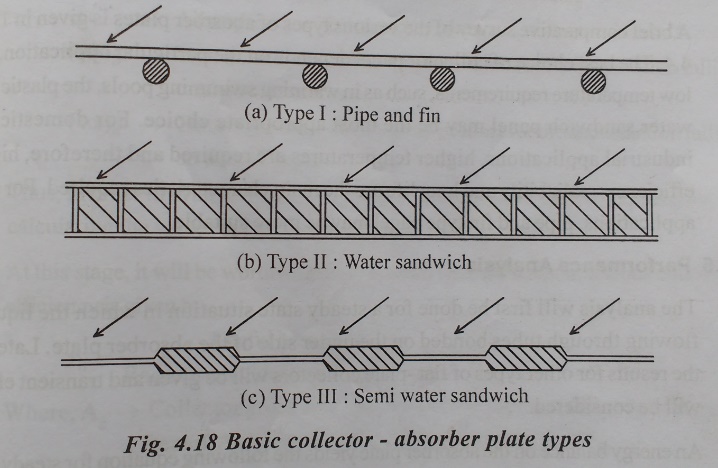

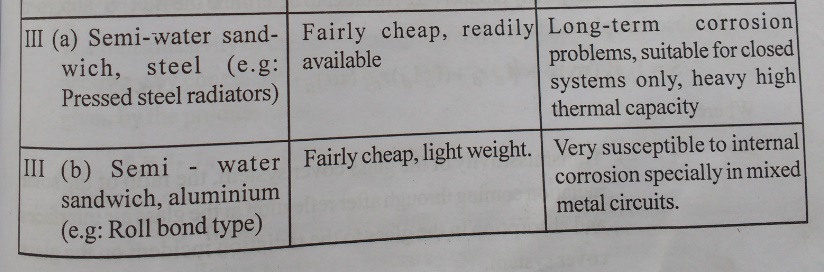

A brie comparative survey o the various types of absorber plates is given in Table 4.4. The best choice of collector panel depends on the particular application. For low temperature requirements, such as in warming swimming pools, the plastic, full water sandwich panel may be the most appropriate choice. For domestic and industrial applications, higher temperatures are required and therefore , higher efficiency, realiability and long life are the main characteristics required. For such applications, pipe and fin type panel may be more suitable.

Related Topics