Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Subgrade and Formation

Failure of Railway Embankment

Failure of

Railway Embankment

A railway

embankment may fail due to the following causes.

(a) Failure

of the natural ground

(b) Failure

of the fill material in the embankment

(c) Failure

of the formation top

Whatever

may be the cause of failure, the normal symptoms are the following.

(a) Variation

in cross levels

(b) Loss of

ballast

(c) Upheaval

of the ground beyond the toes of the embankment

(d) Slips in

bank slopes

These

failures are discussed in the subsequent sections.

1 Failure of Natural Ground

The natural ground on which the

embankment is made can fail either due to shear failure or due to excessive

settlement. Failure of this kind is generally associated with the upheaval of

the ground beyond the toes of the embankment. Shear failure of natural ground

generally takes place when construction is in progress or immediately after

construction. Once the ground stabilizes, it hardly fails under existing

embankments.

The following remedial measures

are generally adopted to improve the load-carrying capacity of natural ground

and hasten the process of settlement.

(a) Provision

of suitably spaced sheet or ordinary piles on either side of the embankment,

which will check shear failure by obstructing the slipping mass.

(b) Provision

of a balancing embankment to increase the load on the natural ground to check

its heaving tendency.

(c) Provision

of sand drains to help quicker consolidation.

2 Failure of the Fill Material of

Embankments

Sometimes shear failure and

excessive settlement of an embankment takes place due to the failure of the

fill material of the embankment. This can easily be avoided by judicious

selection of the fill material, better construction procedures, and adopting a

suitably designed section for a new embankment. The main reasons for this type

of failure are the following.

(a) Heavy

traffic causing excessive stress in the soil, beyond its safe limit

(b) Inadequate

side slopes of the bank

(c) Percolation

of water in the embankment, thereby increasing the weight of the soil on one

hand and reducing its bearing capacity and shear resistance on the other. Shear

failure of existing embankments is quite common and occurs due to slips. Other

causes of failure are the weights of the embankment and the moving loads on it.

The forces resisting the failure are the cohesion

and

internal friction of the fill material.

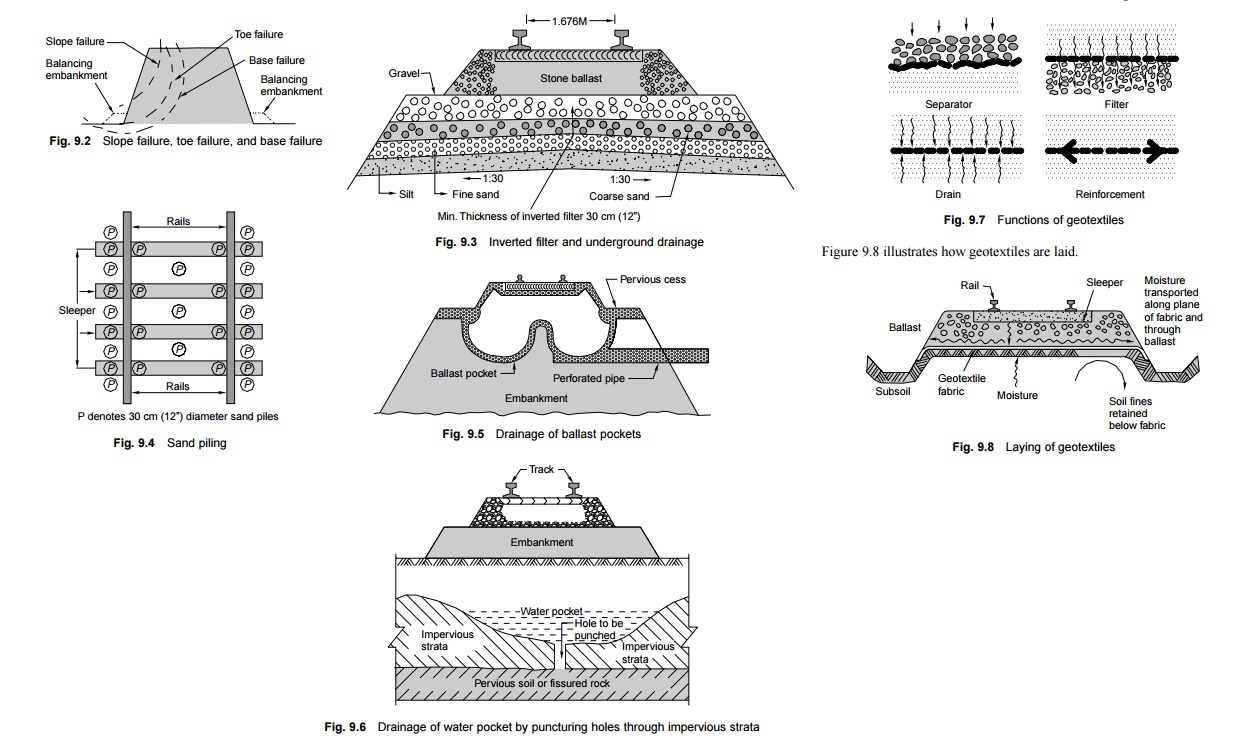

The following types of slip

failures may occur along different planes, as shown in Fig. 9.2.

l A slip

passing through the toe of the bank known as toe failure.

l A slip

passing below the toe of the bank through its base known as base failure.

l A slip

passing above the toe of the bank through its slope known as slope failure.

The

remedies effective for such failures are listed below.

(a) Providing

vertical piles on the slope on either side of the track, spaced at suitable

intervals. These piles, which may be of scrap rail, bullies, etc., help check

shear failure by causing an obstruction for the slip mass. This method was

adopted on Ganga Bridge, Mokameh, and was found to be quite successful.

(b) Providing

balancing embankments on either side of the embankment as shown in Fig. 9.2.

(c) Flattening

the side slopes.

(d) Reducing

the height of the embankment.

(e) Providing

a lighter material at the top of the embankment, replacing the older material.

(f) Providing

proper surface and sub-surface drainage.

3 Failure of Formation Top

Failure of the formation top is

very common in clayey soils during or just after monsoons. Some locations may

trouble throughout the year. The main causes for such failures are the

following.

Low bearing capacity of the soil Sinking

of the ballast and the track, and the heaving up of cesses and bulging

of side slopes as a consequence. The ballast punches into the formation causing

ballast pockets.

Action of water and moving loads The top

soil becomes soft and gets pumped up resulting in the sinking of the

ballast. The ballast also gets clogged and looses its drainage property.

Effect of weather Cracks

develop on the formation during the summer months and the ballast sinks

through the cracks, resulting in the settlement of the track. The situation

gets further worsened during the monsoons when water seeps through these

cracks, turning the upper layers of the formation to slush and resulting in the

formation of deeper ballast pockets.

The impact of moving loads and

the development of hydrostatic pressure further deepens the ballast on the side

slopes as well and can lead to slips in extreme cases. These failures present

considerable problems in the maintenance of the track. Not only is the track

geometry affected thereby requiring frequent attention, but also huge

quantities of ballast are lost every year, making its maintenance difficult and

expensive.

The

following remedial measures can be adopted depending upon the situation.

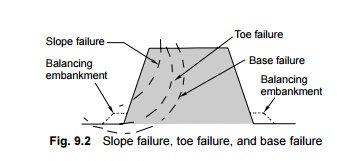

Provision of an inverted filter

The bearing capacity of the soil

is improved by the provision of a blanket of adequate thickness (inverted

filter, Fig. 9.3) between the ballast and the weak formation. The blanket

should be of a non-cohesive material with adequate bearing capacity to

withstand the load thereon. The blanketing material should conform to the

following specifications.

(a) The

liquid limit of the blanketing material should not be greater than 35 and the

plasticity index should not be greater than 15.

(b) The

blanketing material should have such a grain size that the fine soil from the

bottom does not mix up with the water. The material should, therefore, conform

to the specifications of an inverted filter.

(c) The

blanketing material should be well graded, starting from a fine size to a size

slightly smaller than stone ballast, the finer size lying at the bottom.

The inverted filter blanket is a

very effective method of improving the bearing capacity of the soil. It serves

as a barrier for the upward movement of the clay. It also provides a porous

medium to drain off the surface water. The blanket also works as a capillary

cut-off layer. The blanket can be inserted by imposing a traffic block of 4-5

hours or by temporarily operating only one line.

Improvement of surface drainage

Surface drainage can be improved

by diverting ground water, providing catch water drains, etc., as well as

draining the sub-surface structure.

Cement grouting

For cement grouting, a slurry or

grout of cement and sand is pumped into the embankment by pneumatic injections.

A 25-mm-diameter steel pipe is coupled with a rubber hose pipe of the same

diameter, and through this grout of cement and sand in the ratio of 1:2 to 1:6

is injected under a pressure of 60 psi with the help of a pneumatic hammer. The

injection points are kept close to both ends of the sleeper in a staggered

position at an interval of 1.5 m or so. Pumping is continued till the grout

appears through the ballast and reaches its top surface.

Cement grouting is considered to

be a very effective method of treating the subgrade. It fills the cracks,

preventing the water from flowing into the subgrade, and seals off the moisture

entering into it. The soil is stabilized and develops better properties and

strength.

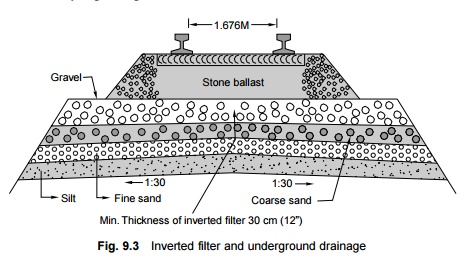

Sand piling

In sand piling (Fig. 9.4), a series of 30-cm-diameter holes

are drilled vertically inside and outside the rail to a depth of 2-3 m by means

of augers or other devices. The holes are then filled up with clean sand and

the track is resurfaced (Fig. 9.4). The sand piles are so arranged that the

cross-sectional area of the sand piles is about 20% of the formation area. Sand

piles compact the soil and provide mechanical support to the subgrade just like

wooden piles. The drainage of the subgrade also improves, as water rises to the

surface through the sand piles by capillary action and evaporates.

Deep screening of ballast and drainage of

water pockets

The problem of ballast pockets can

be tackled by assessing the depth of the penetration of the ballast in the

bank. For this purpose, about five vertical trial bores are drilled to get a

complete picture of the drainage condition of the sub-surface structure. Water

pockets can then be removed by any of the following methods, depending upon the

situation.

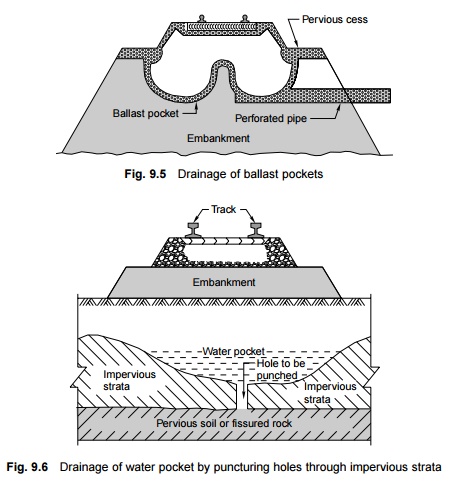

(a) If the

problem has just started, it can be remedied by deep screening and the

provision of a pervious layer of 30-60 cm on the cess. If necessary, the water

pockets can be drained using a perforated pipe drain inserted with the help of

a jack, as shown in Fig. 9.5.

(b) Cement

grouting can also be done to seal the water pockets in case the problem is in a

very small stretch. This method is, however, very expensive.

(c) If the

problem is extensive, a geological survey should be done to assess the type of

soil strata available. In case there is impervious soil under the water pocket,

it can be drained out using a perforated pipe (Fig. 9.5)-deep screening of the

ballast is done, the water pockets are drained out using a perforated pipe, and

then an inverted filter of about 30 cm thickness is provided.

(d) Counterfeit

drains are sometimes provided to drain the water pockets. Such drains are

generally 60 cm wide and spaced at intervals of 10 m or so, depending upon the

extent of the problem.

(e) Water may

also be held up in the ballast pockets by an impervious layer of soil over a

good pervious layer of soil of fissured strata. In this case the remedy lies in

drilling a tap hole in the thin impervious strata, allowing the water to go into the pervious subsoil, where

it gets drained automatically (Fig. 9.6).

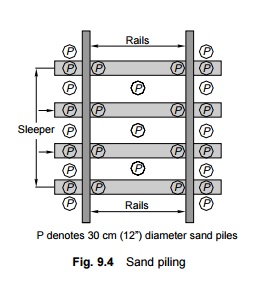

4 Soil Stabilization by Geotextiles

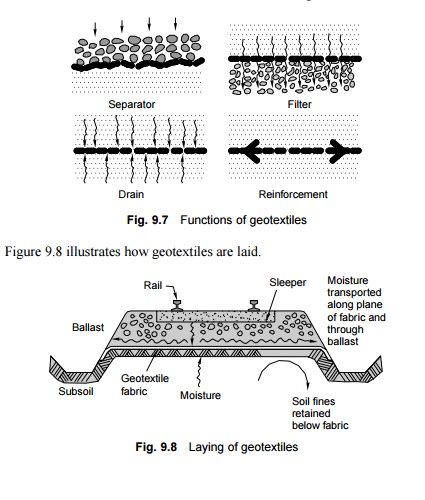

A new method of stabilization of

soil using geotextiles has recently been developed in many countries.

Geotextiles are made up of polymers and have the unique property of allowing

water, but not soil fines, to pass through. Geotextiles not only work as

separators and filters but also help drain the water and provide reinforcement

to the soil bed (Fig. 9.7).

A layer of geotextile is normally either laid directly below

the ballast or sandwiched between layers of sand. On Indian Railways, the

geotextile is proposed to be sandwiched between a 50-mm layer of sand on top

and a 25-mm layer of sand below so that the ballast does not rest directly on

the geotextile and incidences of tear and puncture are reduced.

Related Topics