Chapter: Aquaculture Engineering : Aeration and Oxygenation

Example of designs for different types of aerator: Gravity, Surface, Subsurface aerators

Example of designs for different types of aerator

Many types of aerators are available, and different classifications are possible depending on the design principles employed. One classification is surface, subsurface and gravity aerators, another is mechanical, gravity and air diffusion systems, while a third is gravity, surface, diffusers and turbine aerators.

In gravity aerators the water falls under gravity and air is mixed into it from the surrounding atmosphere. The simplest type is an artificial waterfall. Gravity aerators require water with natural pressure (head); otherwise the water must be pumped up and into the aerator. In a surface aerator the water is sprayed or splashed into the air with a mechanical device; it functions on the same principle as a water fountain and creates a large surface area where gas exchange can occur. In sub-surface aerators air is directed under the water surface, which creates air bubbles that go to the surface; the air bubbles in the water create a large gas transfer surface.

The design of the aerator will, as mentioned before, vary depending on the main purpose of the aerator, whether it is designed for adding oxygen, or removing nitrogen or carbon dioxide. Even if all aerators have some effect on all the gases, the effect is not necessarily optimal. Below is a brief review of some major types of aerator.

Gravity aerators

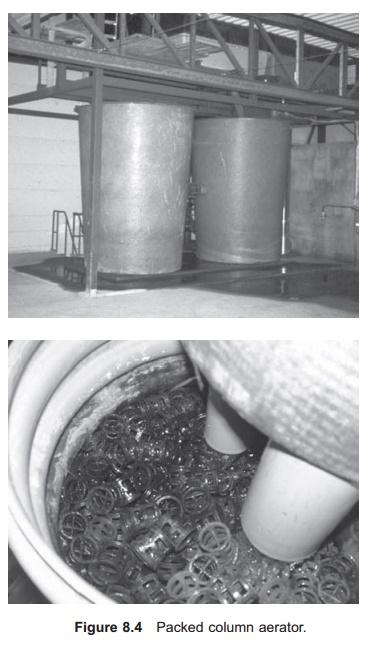

The packed column aerator is one of the most com-monly used in intensive fish farming (Fig. 8.4). A column is filled with a medium with a large specific surface area. A dispersal plate (perforated plate) installed at the top of the column, over the aeration medium, ensures proper distribution through the total cross-sectional area of the water that enters the top of the column. There is also a perforated plate in the bottom of the column to keep the medium stable inside. The water trickles down the column on the surface of the aeration medium in a thin film. This arrangement creates a large area between the flowing water and the air around it and ensures effective gas exchange. It is, however, important to get sufficient air into the aerator. An open structured column can therefore be advanta-geous, or a fan that blows air through the column can be used (see later). The aeration medium is commonly plastic, and it has a design that creates a large surface area per unit volume. The relation between the surface area (A) and the volume (V) is called the A/V condition for the medium. For effective aeration media an A/V value of between 100 and 200 m2/m3 is normal; if the value is too high, the possibilities for blockage of the column increase. To give satisfactory aeration under practi-cal conditions the column ought to be up to 2 m in height. This, however, depends on the medium, the

flow rate and the water temperature.18 The diame-ter of the column cylinder depends on the quantity of water to be aerated, but is normally between 30 and 100 cm. If the diameter is too small, the pro-portion of the water flow against the wall in the column, where reduced aeration is achieved, will increase; a design rule of thumb value is 0.5–1 l water/min/cm2 cross-sectional area. The advantage with a column aerator compared to other aerators is the low surface requirement. Column aerators are effective with reported SAE values of 1.5– 2.0 kg O2/kWh.12This type of aerator also shows quite good results for removal of nitrogen.20

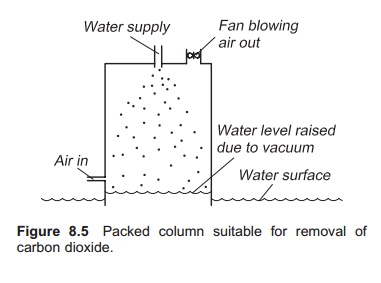

To remove carbon dioxide from the water is quite difficult because the amounts are so small (less than1% of the total gas volume) and it is rather more soluble than oxygen.7 Therefore, an aerator that is suitable for removing nitrogen and adding oxygen may not be so suitable for carbon dioxide removal. What is normally needed is alarge flow of air through the water: 3–10 volumes of air for every 1 volume of water flow treated has been suggested.21 Specially designed packed column aer-ators have proved effective for this purpose.22 Either a long (several metres) packed column aerator or a short packed column with a fan blowing air through to increase the air flow can be used (Fig. 8.5).

A packed column aerator may also be set under low pressure. The principle here is that the water isaerated in a low pressure atmosphere. Thus the amounts of gases that can be dissolved in the water are reduced (Henry–Dalton law states that by reducing the pressure of the gas the amount of dis-solved gases will be reduced) and it is possible to reduce the saturation in the water to below 100% by natural pressure. This method is especially useful when growing species that have a low tolerance against super-saturation, such as marine fry.19 Ejector aerators will also have this advantage.

Packed column aerators are normally placed a certain distance above a level basin to achieve the best possible air transport through the aerator. This is important for the aeration results. Normally the distance is set to 10 cm. Too great a distance between column and basin must, however, be avoided because if the water drops from the aerator fall into the level basin with too high a velocity, air will be dragged into the water together with the water drop and some super-saturation of nitrogen might result. This can be harmful to critical life stages.

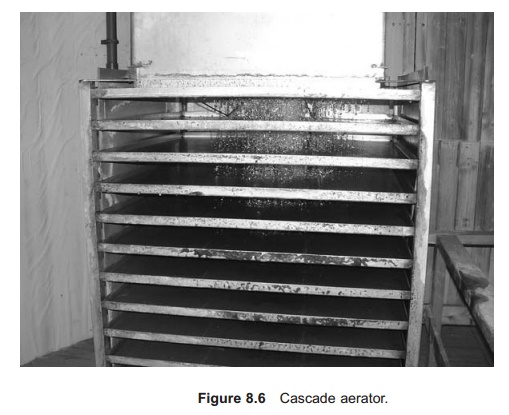

Another much used aerator type is the cascade aerator (Fig. 8.6). Water is supplied at the top and flows over a series of horizontal perforated plates or trays placed on top of each other. Vertical dis-tances between the trays are typically 10–25 cm, and the number of trays between 4 and 10.18Theeffec-tiveness of the aerator increasing with number of

trays and distance between them. At least 10 trays are recommended if using 10 cm between them. The water is distributed throughout the whole perfo-rated tray and drops down from tray to tray until it reaches the level basin located underneath the last one. When the water flows down through the holes in the perforated trays, drops will be created and this ensures a large contact area between the air and the water. The space requirement for a cascade aerator is much higher than for the column aerator; the recommended hydraulic rate is down to one-tweflth of what is recommended for a packed column aerator.

Typical SAE values for gravity aerators are in the range 0.6 to 2.4 kg O2/(kW h).

Subsurface aerators

Diffusers are commonly used as subsurface aer-ators. A diffuser is a construction where small bubbles of gas are created: the simplest form is a tube with holes. If air is pumped in and the tube lowered under the water surface, the air will come out in the water as bubbles. Tubes with many small holes may also be specially produced for use as dif-fusers; porous ceramic stones may also be used. A large transfer surface is created by air bubbles going through the water. Bubble size depends on the difference in the pressure inside the bubble and around the bubble. A high pressure difference gives smaller bubbles. Smaller bubbles will give a greater total surface area and by this gas transfer area. The rise velocity is also slower for smaller bubbles which increases the gas transfer rate.23 SAE values vary from 0.6–2.0 depending on the bubble size,1higher values being achieved with smaller bubbles.11 Bubbles that are too small will, however, be pushed together to create large bubbles, and are therefore not effective. As mentioned previously, when mixing air under pressure, care should be taken to avoid super-saturation with nitrogen which may occur if air is to be added below 1.5–2 m depth, or the pressure is over 0.15–0.2 bar.

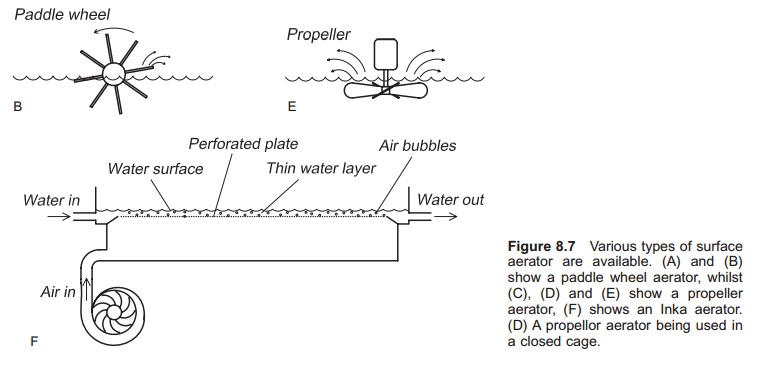

In the Inka aerator the incoming water flows over a perforated plate in a thin layer (Fig. 8.7). An air blower supplies air from the underside. The air will create bubbles that flow through the thin water layer and aeration is achieved. An Inka aerator requires a large surface area but the head loss is very low. Therefore it may, for example, be installedunder the roof on a fish farm. The aerator type is less used than those described previously, but is useful for special conditions.

Venturi and air-lift pumps are other principles that can be used for aeration where air bubbles are supplied into a water flow; SAE values are in the range 2–3.3 kg O2/(kW h).

Surface aerators

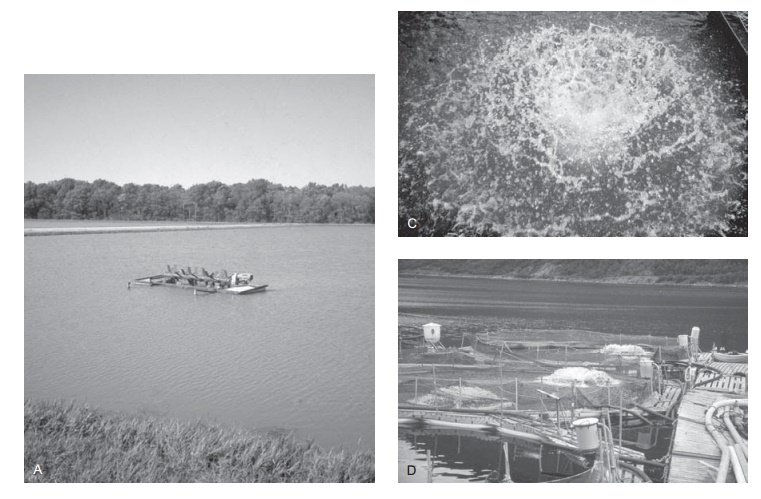

Surface aerators are commonly use in ponds, but may also be used in large tanks, in distribution basins and in sea cages under special conditions (Fig. 8.7). A great number of different designs of surface aerators are available. Normal designs use rotating wheels with a type of paddle, or horizon-tally placed propellers. They function by throwing the water into the air and creating thin films or bubbles. This establishes a large exchange surface area between water and air where gas exchange can take place. Surface aerators are driven by electricity, solar power or from tractors through a shaft; SAE values are between 1.2 and 2.9 kg O2/(kW h).

Related Topics