Chapter: Principles of Management

Evolution of Management Thought

EVOLUTION OF MANAGEMENT THOUGHT

The practice of management is as old as human civilization. The ancient

civilizations of Egypt (the great pyramids), Greece (leadership and war tactics

of Alexander the great) and Rome displayed the marvelous results of good

management practices.

The origin of management as a discipline was developed in the late 19th

century. Over time, management thinkers have sought ways to organize and

classify the voluminous information about management that has been collected

and disseminated. These attempts at classification have resulted in the

identification of management approaches. The approaches of management are

theoretical frameworks for the study of management. Each of the approaches of

management are based on somewhat different assumptions about human beings and

the organizations for which they work.

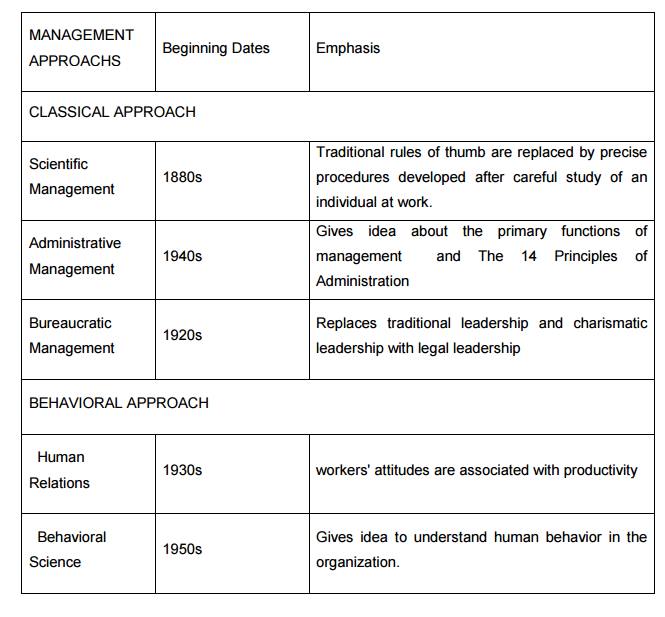

The different approaches of management are a) Classical approach,

Behavioral

approach,

Quantitative approach,

Systems approach,

Contingency approach.

The formal

study of management is largely a twentieth-century phenomenon, and to some

degree the relatively large number of management approaches reflects a lack of

consensus among management scholars about basic questions of theory and

practice.

a) THE CLASSICAL APPROACH:

The

classical approach is the oldest formal approach of management thought. Its

roots pre-date the twentieth century. The classical approach of thought

generally concerns ways to manage work and organizations more efficiently.

Three areas of study that can be grouped under the classical approach are

scientific management, administrative management, and bureaucratic management.

(i)

Scientific Management.

Frederick Winslow Taylor is known as the father of scientific

management. Scientific management (also called Taylorism or the Taylor system)

is a theory of management that analyzes and synthesizes workflows, with the

objective of improving labor productivity. In other words, Traditional rules of

thumb are replaced by precise procedures developed after careful study of an

individual at work.

(ii)

Administrative Management.

Administrative management focuses on the management process and

principles of management. In contrast to scientific management, which deals

largely with jobs and work at the individual level of analysis, administrative

management provides a more general theory of management. Henri Fayol is the

major contributor to this approach of management thought.

(iii)

Bureaucratic Management.

Bureaucratic management focuses on the ideal form of organization. Max

Weber was the major contributor to bureaucratic management. Based on

observation, Weber concluded that many early organizations were inefficiently

managed, with decisions based on personal relationships and loyalty. He

proposed that a form of organization, called a bureaucracy, characterized by

division of labor, hierarchy, formalized rules, impersonality, and the

selection and promotion of employees based on ability, would lead to more

efficient management. Weber also contended that managers' authority in an

organization should be based not on tradition or charisma but on the position

held by managers in the organizational hierarchy.

b) THE BEHAVIORAL APPROACH:

The behavioral approach of management thought developed, in part,

because of perceived weaknesses in the assumptions of the classical approach.

The classical approach emphasized efficiency, process, and principles. Some

felt that this emphasis disregarded important aspects of organizational life,

particularly as it related to human behavior. Thus, the behavioral approach

focused on trying to understand the factors that affect human behavior at work.

(i) Human

Relations.

The Hawthorne Experiments began in 1924 and continued through the early

1930s. A variety of researchers participated in the studies, including Elton

Mayo. One of the major conclusions of the Hawthorne studies was that workers'

attitudes are associated with productivity. Another was that the workplace is a

social system and informal group influence could exert a powerful effect on

individual behavior. A third was that the style of supervision is an important

factor in increasing workers' job satisfaction.

(ii)

Behavioral Science.

Behavioral science and the study of organizational behavior emerged in

the 1950s and 1960s. The behavioral science approach was a natural progression

of the human relations movement. It focused on applying conceptual and

analytical tools to the problem of understanding and predicting behavior in the

workplace.

The behavioral science approach has contributed to the study of

management through its focus on personality, attitudes, values, motivation,

group behavior, leadership, communication, and conflict, among other issues.

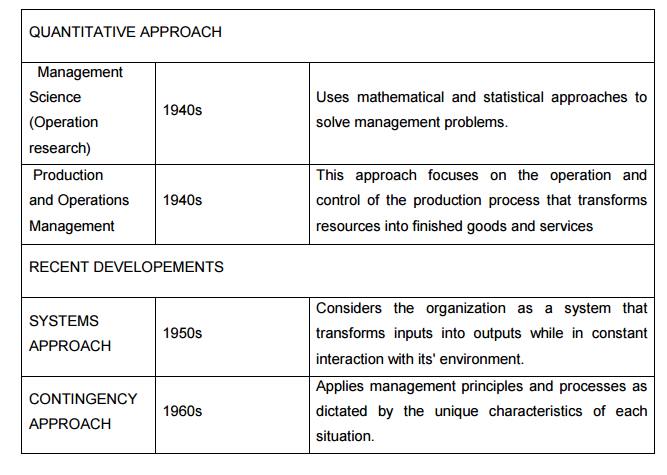

c) THE QUANTITATIVE APPROACH:

The quantitative approach focuses on improving decision making via the

application of quantitative techniques. Its roots can be traced back to

scientific management.

(i)

Management Science (Operations Research)

Management science (also called operations research) uses mathematical

and statistical approaches to solve management problems. It developed during

World War II as strategists tried to apply scientific knowledge and methods to

the complex problems of war. Industry began to apply management science after

the war. The advent of the computer made many management science tools and

concepts more practical for industry

(ii)

Production And Operations Management.

This approach focuses on the operation and control of the production

process that transforms resources into finished goods and services. It has its

roots in scientific management but became an identifiable area of management

study after World War II. It uses many of the tools of management science.

Operations management emphasizes productivity and quality of both

manufacturing and service organizations. W. Edwards Deming exerted a tremendous

influence in shaping modern ideas about improving productivity and quality.

Major areas of study within operations management include capacity planning,

facilities location, facilities layout, materials requirement planning,

scheduling, purchasing and inventory control, quality control, computer

integrated manufacturing, just-in-time inventory systems, and flexible

manufacturing systems.

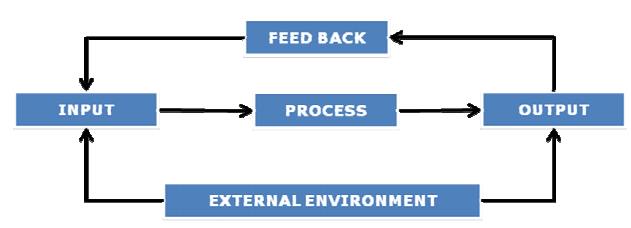

d) SYSTEMS APPROACH:

The simplified block diagram of the systems

approach is given below.

The

systems approach focuses on understanding the organization as an open system

that transforms inputs into outputs. The systems approach began to have a

strong impact on management thought in the 1960s as a way of thinking about

managing techniques that would allow managers to relate different specialties

and parts of the company to one another, as well as to external environmental

factors. The systems approach focuses on the organization as a whole, its

interaction with the environment, and its need to achieve equilibrium

e)

CONTINGENCY APPROACH:

The

contingency approach focuses on applying management principles and processes as

dictated by the unique characteristics of each situation. It emphasizes that

there is no one best way to manage and that it depends on various situational

factors, such as the external environment, technology, organizational

characteristics, characteristics of the manager, and characteristics of the

subordinates. Contingency theorists often implicitly or explicitly criticize

the classical approach for its emphasis on the universality of management

principles; however, most classical writers recognized the need to consider

aspects of the situation when applying management principles.

CONTRIBUTION OF FAYOL AND TAYLOR

F.W. Taylor and Henry

Fayol are generally regarded as the founders of scientific management and

administrative management and both provided the bases for science and art of

management.

Taylor's

Scientific Management

Frederick

Winslow Taylor well-known as the founder of scientific management was the first

to recognize and emphasis the need for adopting a scientific approach to the

task of managing an enterprise. He tried to diagnose the causes of low

efficiency in industry and came to the conclusion that much of waste and

inefficiency is due to the lack of order and system in the methods of

management. He found that the management was usually ignorant of the amount of

work that could be done by a worker in a day as also the best method of doing

the job. As a result, it remained largely at the mercy of the workers who

deliberately shirked work. He therefore, suggested that those responsible for

management should adopt a scientific approach in their work, and make use of

"scientific method" for achieving higher efficiency. The scientific

method consists essentially of

Observation

Measurement

Experimentation and

Inference.

He

advocated a thorough planning of the job by the management and emphasized the

necessity of perfect understanding and co-operation between the management and

the workers both for the enlargement of profits and the use of scientific

investigation and knowledge in industrial work. He summed up his approach in

these words:

Science, not rule of

thumb

Harmony, not discord

Co-operation, not

individualism

Maximum output, in

place of restricted output

The development of

each man to his greatest efficiency and prosperity.

Elements of Scientific Management: The techniques which Taylor regarded as its

essential elements or features may

be classified as under:

Scientific Task and

Rate-setting, work improvement, etc.

Planning the Task.

Vocational Selection

and Training

Standardization (of

working conditions, material equipment etc.)

Specialization

Mental Revolution.

1. Scientific Task and Rate-Setting (work

study): Work study may be defined as the systematic, objective and critical

examination of all the factors governing the operational efficiency of any

specified activity in order to effect improvement.

Work study

includes.

Methods

Study: The management should

try to ensure that the plant is laid out in the best manner and is equipped with the best tools and machinery. The

possibilities of eliminating or combining certain operations may be studied.

Motion Study: It is a study of the movement, of an operator (or even of a machine) in

performing an operation with the purpose of eliminating useless motions.

Time Study (work measurement): The basic purpose of time study is to determine

the proper time for performing the

operation. Such study may be conducted after the motion study. Both time study

and motion study help in determining the best method of doing a job and the

standard time allowed for it.

Fatigue Study: If, a standard task is set without providing for

measures to eliminate fatigue, it

may either be beyond the workers or the workers may over strain themselves to

attain it. It is necessary, therefore, to regulate the working hours and

provide for rest pauses at scientifically determined intervals.

Rate-setting: Taylor recommended the differential piece wage system, under which

workers performing the standard task

within prescribed time are paid a much higher rate per unit than inefficient

workers who are not able to come up to the standard set.

Planning the Task: Having set the task which an average worker must

strive to perform to get wages at

the higher piece-rate, necessary steps have to be taken to plan the production

thoroughly so that there is no bottlenecks and the work goes on systematically.

Selection and Training: Scientific Management requires a radical change

in the methods and procedures of

selecting workers. It is therefore necessary to entrust the task of selection

to a central personnel department. The procedure of selection will also have to

be systematised. Proper attention has also to be devoted to the training of the

workers in the correct methods of work.

Standardization: Standardization may be introduced in respect of

the following.

Tools and equipment: By standardization is meant the process of

bringing about uniformity. The

management must select and store standard tools and implements which will be

nearly the best or the best of their kind.

Speed: There is usually an optimum speed for every machine. If it is exceeded,

it is likely to result in damage to

machinery.

Conditions of Work: To attain standard performance, the maintenance

of standard conditions of

ventilation, heating, cooling, humidity, floor space, safety etc., is very

essential.

Materials: The efficiency of a worker depends on the quality of materials and the

method of handling materials.

Specialization: Scientific management will not be complete

without the introduction of specialization.

Under this plan, the two functions of 'planning' and 'doing' are separated in

the organization of the plant. The `functional foremen' are specialists who

join their heads to give thought to the planning of the performance of

operations in the workshop. Taylor suggested eight functional foremen under his

scheme of functional foremanship.

The Route Clerk: To lay down the sequence of operations and

instruct the workers concerned about

it.

The

Instruction Card Clerk: To

prepare detailed instructions regarding different aspects of work.

The Time and Cost Clerk: To send all information relating to their pay to

the workers and to secure proper

returns of work from them.

The Shop Disciplinarian: To deal with cases of breach of discipline and

absenteeism.

The Gang Boss: To assemble and set up tools and machines and to

teach the workers to make all their

personal motions in the quickest and best way.

The Speed Boss: To ensure that machines are run at their best

speeds and proper tools are used by

the workers.

The Repair Boss: To ensure that each worker keeps his machine in

good order and maintains cleanliness

around him and his machines.

The

Inspector: To show to

the worker how to do the work.

Mental Revolution: At present, industry is divided into two groups

– management and labour. The major

problem between these two groups is the division of surplus. The management

wants the maximum possible share of the surplus as profit; the workers want, as

large share in the form of wages. Taylor has in mind the enormous gain that

arises from higher productivity. Such gains can be shared both by the

management and workers in the form of increased profits and increased wages.

Henry Fayol's 14 Principles of Management:

The

principles of management are given below:

Division of work: Division of work or specialization alone can

give maximum productivity and efficiency.

Both technical and managerial activities can be performed in the best manner

only through division of labour and specialization.

Authority and Responsibility: The right to give order is called authority. The

obligation to accomplish is called

responsibility. Authority and Responsibility are the two sides of the

management coin. They exist together. They are complementary and mutually

interdependent.

Discipline: The objectives, rules and regulations, the policies and procedures must

be honoured by each member of an

organization. There must be clear and fair agreement on the rules and

objectives, on the policies and procedures. There must be penalties

(punishment) for non-obedience or indiscipline. No organization can work

smoothly without discipline - preferably voluntary discipline.

Unity of Command: In order to avoid any possible confusion and

conflict, each member of an

organization must received orders and instructions only from one superior

(boss).

Unity of Direction: All members of an organization must work

together to accomplish common

objectives.

Emphasis on Subordination of Personal Interest

to General or Common Interest: This is also called principle

of co-operation. Each shall work for all and all for each. General or common

interest must be supreme in any joint enterprise.

Remuneration: Fair pay with non-financial rewards can act as the best incentive or

motivator for good performance.

Exploitation of employees in any manner must be eliminated. Sound scheme of

remuneration includes adequate financial and nonfinancial incentives.

Centralization: There must be a good balance between

centralization and decentralization of authority

and power. Extreme centralization and decentralization must be avoided.

Scalar Chain: The unity of command brings about a chain or hierarchy of command

linking all members of the

organization from the top to the bottom. Scalar denotes steps.

Order: Fayol suggested that there is a place for everything. Order or system

alone can create a sound

organization and efficient management.

Equity: An organization consists of a group of people involved in joint effort.

Hence, equity (i.e., justice) must

be there. Without equity, we cannot have sustained and adequate joint collaboration.

Stability of Tenure: A person needs time to adjust himself with the

new work and demonstrate efficiency

in due course. Hence, employees and managers must have job security. Security

of income and employment is a pre-requisite of sound organization and

management.

Esprit of Co-operation: Esprit de corps is the foundation of a sound

organization. Union is strength. But

unity demands co-operation. Pride, loyalty and sense of belonging are

responsible for good performance.

Initiative: Creative thinking and capacity to take initiative can give us sound

managerial planning and execution of

predetermined plans.

Related Topics