Chapter: Civil : Water Resources and Irrigation Engineering : Diversion and Impounding Structures

Earthen Dams and Rock Fill Dams

Earthen Dams and Rock Fill Dams

Introduction

Earthen

dams and earthen levees are the most ancient type of embankments, as they can

be built with the natural materials with a minimum of processing and primitive

equipment. But in ancient days, the cost of carriage and dumping of the dam

materials was quite high. However, the modern developments in earth moving equipments

have considerably reduced the cost of carriage and laying of the dam materials.

The cost of gravity dams on the other hand, has gone up because of an increase

in the cost of concrete, mesonry, etc. Earthen dams are still cheaper as they

can utilize the locally available materials, and less skilled labour is

required for them.

Gravity

dams and arch dams require sound rock foundations, but earthen dams can be

easily constructed on earth foundations. However, earth dams are more

susceptible to failure as compare to rigid gravity dams or arch dams. Before

the development of the subject of Soil-Mechanics, these dams were being

designed and constructed on the basis of experience, as no rational basis for

their design was available. This led to the failure of various such earthen

embankments. However, in these days, these dams can be designed with a fair

degree of theoretical accuracy, provided the properties of the soil placed in

the dam, are properly controlled. This condition makes the design and construction

of such dams, thoroughly interdependent. Continuous field observations of

deformations and pore water pressures have to be made during the construction

of such dams. Suitable modifications in the design, are then made during

construction, depending upon these field observations.

Type of Earthen Dams

The earthen dam can be of the following three types:

1.

Homogeneous

Embankment type

2.

Zone

embankment type

3.

Diaphragm

type.

These three types of dams are described below:

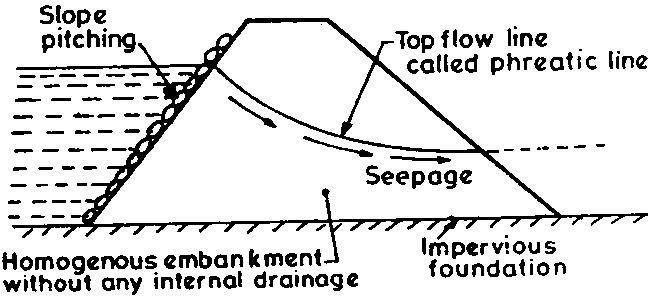

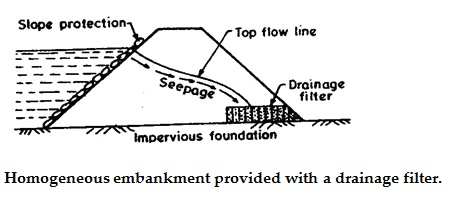

Figure:

(a) Homogenous type embankment

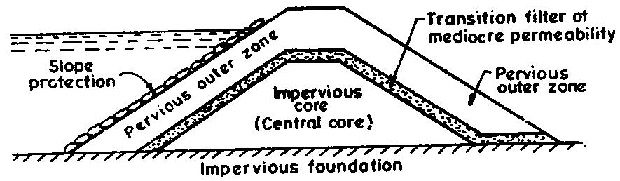

Figure: Zoned type embankment

The

central core checks the seepage. The transition zone prevents piping through

cracks which may develop in the core. The outer zone gives stability to the

central impervious fill and also distribute the load over a large area of

foundations.

This type

of embankment are widely constructed and the materials of the zones are

selected depending upon their availabilities. Caly, inspite of it being highly

impervious, may not make the best core, if it shrinks and swells too much. Due

to this reason, clay is sometimes mixed with fine sand or fine gavel, so as to

use it as the most suitable material for the central impervious core. Silts or

silty clays may be used as the satisfactory central core materials. Freely

draining materials, such as coarse sands and gravels, are used in the outer

shell. Transition filters are provided between the inner zone and the outer

zone, as shown in fig. This type of transition filters are always provided,

whenever there is an abrupt change of permeability from one zone to the other.

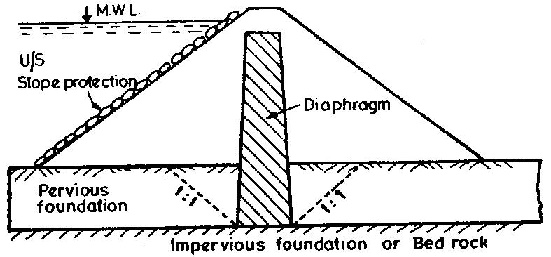

(3) Diaphragm Type Embankments. Diaphragm type embankments have a thin

impervious core, which is surrounded by earth or rock fill. The

impervious core, called diaphragm, is made of impervious soils, concrete,

steel, timber or any other material. It acts as a water barrier to prevent seepage

through the dam. The diaphragm may be placed either at the centre as a central

vertical core or at the upstream face as a blanket. The diaphragm must also be

tied to the bed rock or to a very impervious foundation material, if excessive

under-seepage through the existing previous foundations has to be avoided

(fig.).

Figure: Diaphragm type embankment

The

diaphragm type of embankments are differentiated from zoned embankments,

depending upon the thickness of the core. If the thickness of the diaphragm at

any elevation is less than 10 elevation is less than the height of the

embankment above the corresponding

elevation, the dam embankment is

considered to b equals or exceeds or exceeds these limits, it is considered to

be of zoned embankment type.

Methods of Construction

There are two methods of constructing earthen dams:

(1) Hydraulic-fill Method; and

(2) Rolled-fill Method.

(1) Hydraulic-fill Method. In this method of construction, the

dam body is constructed by excavating and transporting soils by using

water. Pipes called flumes, are laid along the outer edge of the embankment.

The soil materials are mixed with water and pumped into these flumes. The slush

is discharged through the outlets in the flumes at suitable intervals along

their lengths.

The slush, flowing towards the centre

of the bank, tends to settle down. The coarser particles get deposited soon

after the discharge near the outer edge, while the fines get carried and settle

at the centre, forming a zoned embankment having a relatively impervious

central core.

Since the

fill is saturated when placed, high pore pressures develop in the core

material, and the stability of the dam must be checked for these pressures.

This type of embankment is susceptible to settlement over long periods, because

of slow drainage from the core.

Hydraulic-fill

method is, therefore, seldom adopted these days. Rolled-fill method for

constructing earthen dams is, therefore, generally and universally adopted in

these modern days.

(2) Rolled-fill Method. The embankment is constructed by

placing suitable soil materials in thin layers (15 to 30 cm) and

compacting them with rollers. The soil is brought to the site from burrow pits

and spread by bulldozers, ect. In layers. These layers are thoroughly compacted

by rollers of designed weights. Ordinary road rollers can be used fro low

embankments (such as for levees or bunds); while power-operated rollers are to

be used for dams. The moisture content of the soil fill must be properly

controlled. The best compaction can be obtained at a moisture content somewhere

near the optimum moisture content. (The optimum moisture content is the

moisture required for obtaining optimum density in the fill). Compaction of

coarse gravels cannot be properly done by rolling and is best done by vibrating

equipment. Detail of rolling and

compacting different types of soils

are available i by the same author.

Shearing Strength of Soils

Before we

describe the causes of failure of earthen dams and the criteria for their safe

design; we shall review a few important conceptions of soil-mechanics and their

importance in the design of earth dams.

Classification

Irrigation projects, are classified

into two Main categories. They are

1.

Diversion

works

2.

Storage

works

Diversion Works

The

purpose of a diversion work is mainly to raise the water level and divert the

river flows into canals to feed the ayacut. A diversion work consists of an

anicut or a weir across the stream or river, by which the water level could be

raised to divert it into canals on either side of the river or stream.

There is no question of any storage

here.

The main component works in this case

are:

1.

A

weir or Anicut across the river or stream in question

2.

Head

sluices or Head Regulators at either end to feed the canals on either side.

3.

Scour

sluices on either side to prevent silting of the approaches to the Heal

Regulator.

A detailed

design of a

River weir is

given i

Storage Works

In big

irrigation projects, where the river, the main source of water, has enough

flows in the year and which go waste un-utilized, storage works are resorted

to, to conserve the water by creating a reservoir, conserve the flows as far as

possible without detriment to the riparian rights of the areas below the

reservoir on the same river. These projects involving construction of huge

reservoirs are also designed to serve as multipurpose projects. A multipurpose

project means that it should serve the following useful purposes:

1.

Flood

control

2.

Irrigation.

3.

Power

generation.

4.

Navigation.

5.

Improve

fish culture, and

6.

Supply

of drinking water.

A storage work, consists of the following components

1.

A

dam across the river to create a reservoir of adequate capacity to irrigate the

command area, with provision for letting down the surplus water down stream.

2.

Head

Regulators on either side to feed the main canals.

3.

Main

canals and distributory system to feed the commanded area.

Related Topics