Chapter: Special Electrical Machines : Stepping Motor

Drive System and Control Circuitry for Stepper Motor

DRIVE SYSTEM AND CONTROL

CIRCUITRY FOR STEPPER MOTOR

1. DRIVE SYSTEM

The

stepper motor is a digital device that needs binary (digital) signals for its

operation .Depending on the stator construction two or more phases have to be

sequentially switched using a master clock pulse input. The clock frequency determines

the stepping rate, and hence the speed of the motor. The control circuit

generating the sequence is called a translator or logic sequencer.

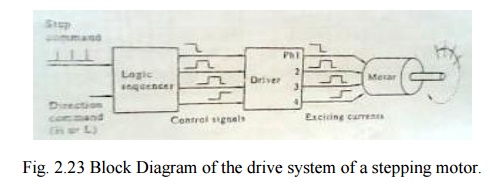

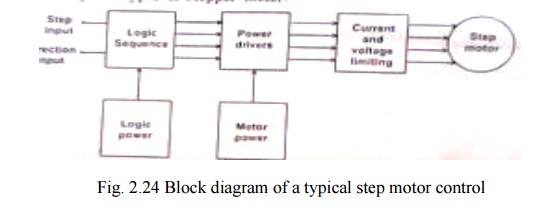

The fig

2.38 shows the block diagram of a typical control circuit for a stepper motor.

It consists of a logic sequencer, power driver and essential protective

circuits for current and voltage limiting. This control circuit enables the

stepper motor to be run at a desired speed in either direction. The power

driver is essentially a current amplifier, since the sequence generator can

supply only logic but not any power. The controller structure for VR or hybrid

types of stepper motor

2. LOGIC SEQUENCER

The logic

sequencer is a logic circuit which control the excitation of the winding

sequentially, responding to step command pulses. A logic sequencer is usually

composed of a shifter register and logic gates such as NANDs, NORs etc. But one

can assemble a logic sequencer for a particular purpose by a proper combination

of JK flip flop, IC chips and logic gate chips.

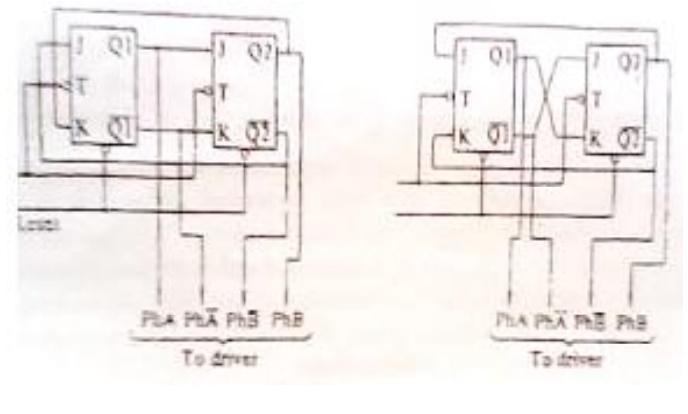

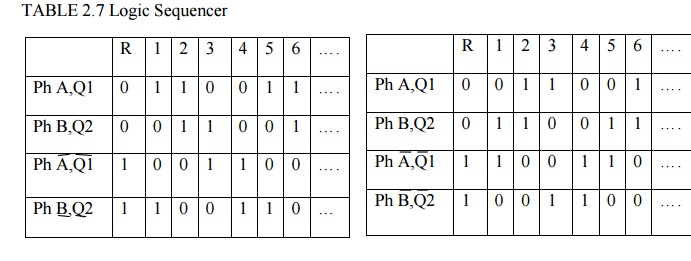

Two

simple types of sequencer build with only two JK-FFs are shown in fig 2.39 for

unidirectional case. Truth tables for logic sequencer also given for both the

directions.

Fig.2.25 A unidirectional logic sequencer for two

phase on operation of a two phase hybrid motor

The

corresponding between the output terminals of the sequencer and the phase

windings to be controlled is as follows.

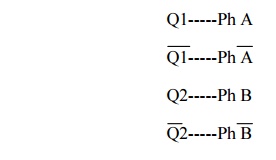

If Q1 is

on the H level the winding Ph A is excited and if Q1is on L level, Ph A is not

excited.

To

reserve the rotational direction, the connection of the sequencer must be

interchanged. The direction switching circuits shown in fig 2.40 may be used

for this purpose. The essential functions being in the combination of three

NAND gates or two AND gates and a NOR gate.

![]()

![]()

3. Power Driver Circuit

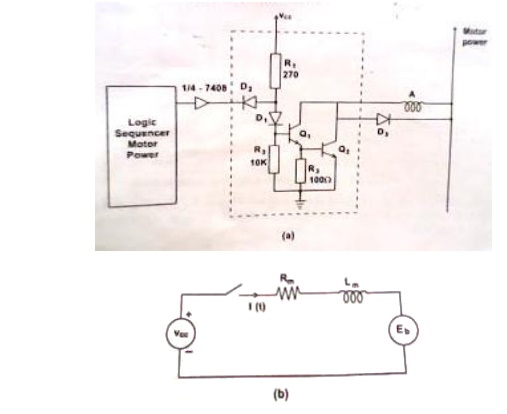

The

number of logic signals discussed above is equal to the number of phases and

the power circuitry is identical for all phases. Fig. 2.44(a) shows the

simplest possible circuit of one phase consisting of a Darlington pair current

amplifier and associated protection circuits. The switching waveform shown in

fig. 2.44(c) is the typical R-L response with an exponential rise followed by

decay at the end of the pulses.

In view

of the inductive switching operation, certain protective elements are

introduced in the driver circuit. These are the inverter gate 7408, the forward

biased diode D1 and the freewheeling diode D. The inverter IC provides some

sort of isolation between the logic circuit and the power driver.

There are

some problems with this simple power circuit. They can be understood by

considering each phase winding as a R-L circuit shown in fig. 2.44(b) subject

to repetitive switching. On application of a positive step voltage, the current

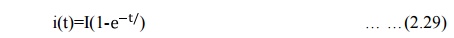

rises exponentially as

Where

I=V/R – rated current and

Ԏ=L/R

winding time constant.

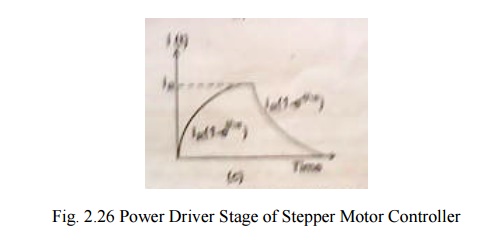

In

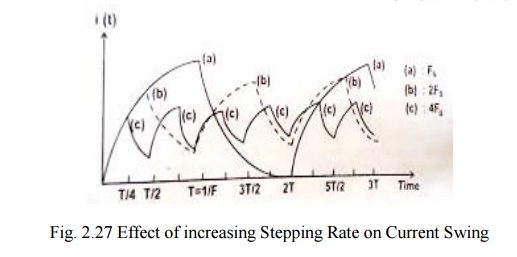

practice, the time constant Ԏ limits the rise and fall of current in the

winding. At low stepping rate the current rises to the rated value in each ON

interval and falls to zero value in each OFF interval. However as the switching

rate increases, the current is not able to rise to the steady state, nor fall

down to zero value with in the on/off time intervals set by the pulse waveform.

This in effect, smoothens the winding current reducing the swing as shown in

fig. 2.45. As a result the torque developed by the motor gets reduced

considerably and for higher frequencies, the motor just ‗vibrates‘ or

oscillates within one step of the current mechanical position.

In order

to overcome these problems and to make improvement of current build up several

methods of drive circuits have been developed.

For

example when a transistor is turned on to9 excite a phase, the power supply

must overcome effect of winding inductances has tendency to oppose the current

built up. As switching frequency increases the position that the buildup time

takes up within the switching cycle becomes large and it results in decreased

torque and slow response.

4. Improvement of current

buildup/special driver circuit

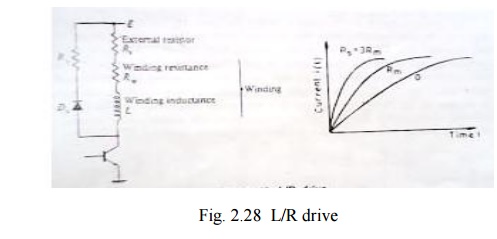

(a) Resistance drive (L/R drive)

Here the

initial slope of the current waveform is made higher by adding external resistance

in each winding and applying a higher voltage proportionally. While this

increases the rate of rise of the current, the maximum value remains unchanged

as shown in fig. 2.46.

The circuit time constant is now reduced and the motor is able to develop normal torque even at high frequencies. The disadvantage of this method is Flow of current through external resistance causesI2R losses and heating. This denotes wastage of power as far as the motor is concerned.

In order

to reach the same steady state current IR as before, the voltage

required

To be

applied is much higher than before. Hence this approach is suitable for small

instrument stepper motor with current ratings around 100 mA, and heating is not

a major problem.

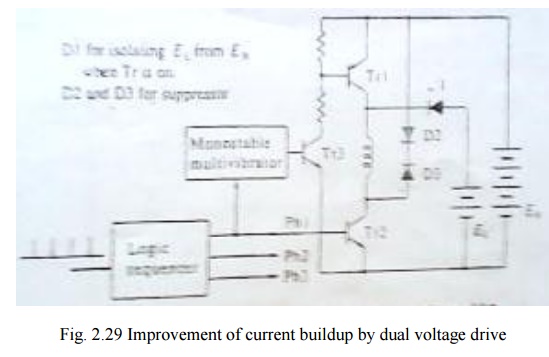

(b) Dual voltage driver (or)

Bi-level driver

To reduce the power dissipation in the driver and

increase the performance of a stepping motor, a dual-voltage driver is used.

The scheme for one phase is shown in fig. 2.47.

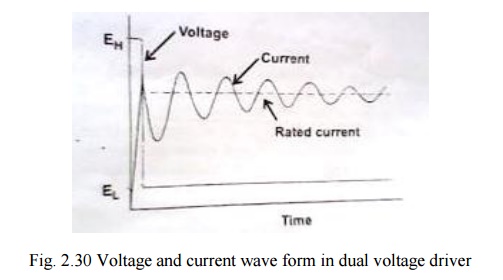

When a

step command pulse is given to the sequencer, a high level signal will be put

out from one of the output terminal to excite a phase winding. On this signal

both T1 and T2 are turned on, and the

higher voltage EHwill be applied to the winding. The diode D1 is now

reverse biased to isolate the lower voltage supply. The current build up

quickly due to the higher voltage EH.

The time constant of the monostable multivibrator is selected so that

transistor T1 is turned off when the winding current exceeds the rated current

by a little. After the higher

Voltage

source is cut off the diode is forward biased and the winding current is

supplied from the lower voltage supply. A typical current wave form is shown in

fig. 2.48.

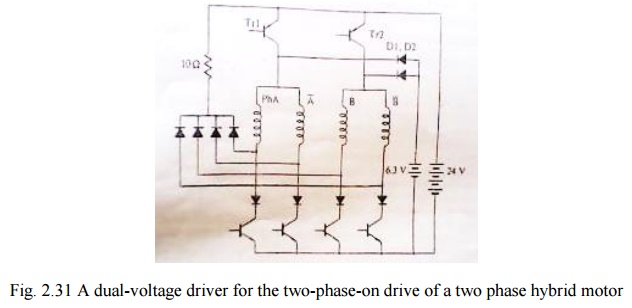

When the dual voltage method is employed for the two phase on drive of a two phase hybrid motor, the circuit scheme will de such as that shown in fig.2.49. Two transistor T 1 &T 2 and two diodes D1 and D2 are used for switching the higher voltage. In dual voltage scheme as the stepping rate is increased, the high voltage is turned on for a greater percentage of time.

This

drive is good and energy efficient. However it is more complex as it requires

two regulated power supplies EH& EL end two power transistor switches Tr1

& Tr2 and complex switching logic. Hence it is not very popular.

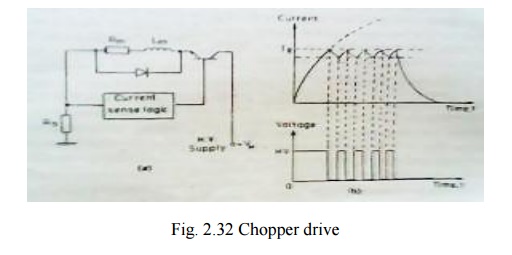

(c)Chopper drive

Here a

higher voltage 5 to 10 times the related value is applied to the phase winding

as shown in fig.2.50(a) and the current is allowed to raise very fast. As soon

as the current reaches about 2 to 5% above the rated current, the voltage is

cut off ,allowing the current to decrease exponentially. Again as the current

reaches some 2 to 5% below the rated value, the voltage is applied again. The

process is repeated some 5-6 times within the ON period before the phase is

switched off. During this period the current oscillates about the rated value

as shown in fig. A minor modification is to chop the applied dc voltage at a

high frequency of around 1khz, with the desired duty cycle so as to obtain the

average on-state current equal to the rated value.

The

chopper drive is particularly suitable for high torque stepper motors. It is

ener4gy efficient like the bi-level drive but the control circuit is simpler.

(d) Problems with driver circuits

A winding

on a stepping motor is inductive and appears as a combination of inductance and

resistance in series. In addition, as a motor revolves a counter emf is

produced in the winding. The equivalent circuit to a winding is hence, such as

that shown for designing a power driver one must take into account necessary

factors and behavior of this kind of circuit. Firstly the worst case3

conditions of the stepping motor, power transistors, and supply voltage must be

considered. The motor parameters vary due to manufacturing tolerance and

operating conditions. Since stepping motors are designed to deliver the highest

power from the smallest size, the case temperature can be as high as about

100°c and the winding resistance therefore increases by 20 to 25 per cent.

Suppressor circuits

These

circuits are needed to ensure fast decay of current through the winding when it

is turned off. When the transistor in the above fig is turned off a high

voltage builds up to Ldi/dt and this voltage may damage the transistor. There

are several methods of suppressing this spike voltage and protecting the

transistor as shown in the following.

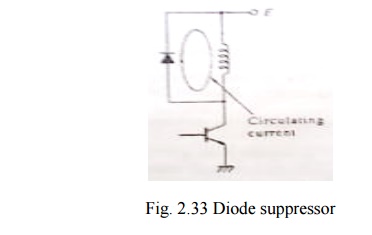

(a) Diode suppressor

If a

diode is put in parallel with the winding in the polarity as shown in fig. a

circulating current will flow after the transistor is turned off, and the

current will decay with time. In this scheme, no big change in current appears

at turn off, and the collector potential is the supply potential E plus the

forward potential of the diode. This method is very simple but a drawback is

that the circulating current lasts for a considerable length of time and it

produces a braking torque.

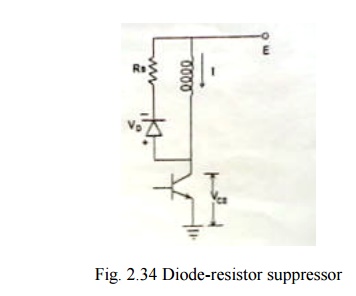

(b)Diode-Resistor suppressor

A

resistor is connected in series with the diode as shown in fig to damp quickly

the circulating current. The voltage VCE applied to the collector at turn-off

in this scheme is

VCE=E+IRS+VD

Where E=

supply potential

I=

Current before turning off

Rs-resistance

of suppressor resistor

VD-forward

potential of diode

A high

resistance RS is required to achieve a quick current decay, but this also

results in a higher collector potential VCE, thus a transistor with a high

maximum voltage rating is necessary.

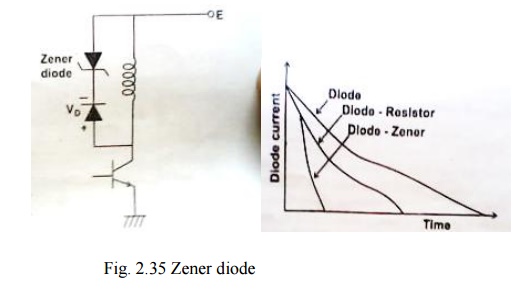

(a) Zener diode suppressor

In this

zener diode are often used to connect in series with the ordinary diode as

shown in fig. Compared with preceding two cases zener diode which provides

negative bias causes the current to decay more quickly after turn off. In

addition to this, it is a merit of this method that the potential applied to

the collector is the supply potential plus the zener potential, independent of

the current. This makes the determination of the rating of the maximum

collector potential easy. However zeners are signal diodes, rather than power

diodes. Their power dissipation is limited to 5w. Consequently, this suppressor

can be used for very small instrument stepper motors of typical size 8 to 11.

Comparison

of effects of various suppressor schemes of various suppressor schemes

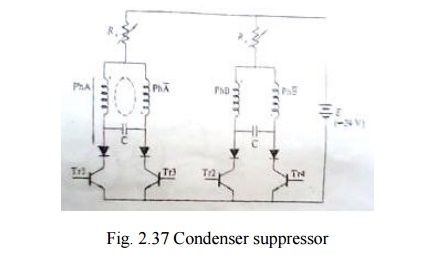

(d)Condenser suppressor

This scheme is often employed for bifilar-wound hybrid motor. An explanation is given for the given for the circuit shown in fig:

A

condenser is put between ph A and ph A1. These condensers serve two fold

purposes.

1. When a

transistor is turned off, the condenser connected to it via a diode absorbs the

decaying current from the winding to protect the transistor.

Let us

see the situation just after the Tr 1 is turned off in the one phase on mode.

Either Tr2 or Tr4 will turn on, but Tr3 will still be in the turned off state .

Since the winding of ph A and ph A1 are wound in the bifilar fashion, a

transient current will circulate in loop. If Tr 3 is turned on when the

transient current becomes zero and the charge stored in the condenser becomes

maximum, a positive current can easily flow through phase A winding. By this

resonance mechanism, currents are used efficiently in this scheme. This feature

remains in the two phase on mode too. The condenser suppressor is suited to

drives in which stepping rate is limited in a narrow range.

2

.Another utility of condensers is as an electrical damper, a method of damping

rotor oscillations is to provide a mechanism to convert kinetic energy to joule

heating. If a rotor having a permanent magnet oscillates, an alternating emf is

generated in the winding. However if a current path is not provided or a high

resistance is connected, no current will be caused by this emf. When the

condenser is connected between phases an oscillatory current will flow in the

closed loop and joule heat is generated in the windings, which means that the

condenser works as an electrical damper.

Related Topics