Chapter: Mechanical and Electrical : Power Plant Engineering : Diesel,Gas Tubine and Combined Cycle Power Plants

Construction and working principle of pumped storage plants

Construction and working principle of pumped storage

plants

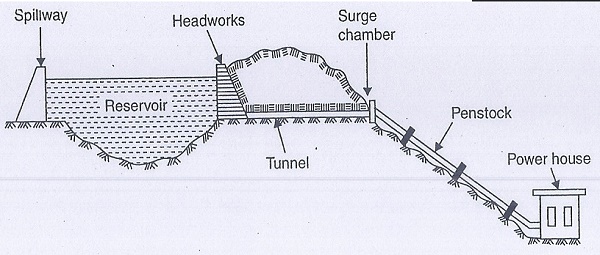

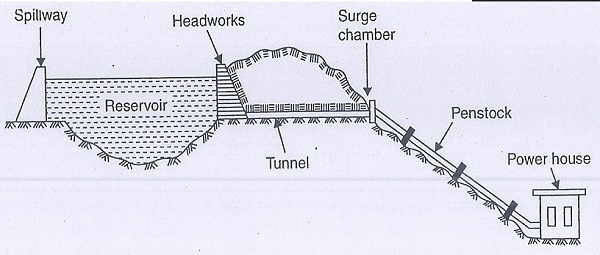

Figure:

Pumped storage plant.

Pumped storage plants are employed at the places where the

quantity of water available for power generation is inadequate. Here the water

passing through the turbines is store in ‘tail race pond’During. low load

periods this water is pumped back to the head reservoir using the extra energy

available. This water can be again used for generating power during peak load

periods. Pumping of water may be done seasonally or daily depending upon the

conditions of the site and the nature of the load on the plant.

Such plants are usually interconnected with steam or

diesel engine pants so that off peak capacity of interconnecting stations is

used in pumping water and the same is used during peak load periods. Of course,

the energy available from the quantity of water pumped water the power

available is reduced on account of losses occurring in prime movers.

Advantages:

The pump

storage plants entail the following advantages :

1.

There

is substantial increase in peak load capacity of the plant at comparatively low

capital cost.

2.

Due

to load comparable to rated load on the plant, the operating efficiency of the

plant is high.

3.

There

is an improvement in the load factor of the plant.

4.

The

energy available during peak load periods is higher than that of during off

peak periods so that inspite of losses incurred in pumping there is over-all

gain.

5.

Load

on the hydro-electric plant remains uniform.

6.

The

hydro-electric plant becomes partly independent of the stream flow conditions.

Under pump storage projects almost 70 percent power used

in pumping the water can be recovered. In this field the use of ‚Reversible

Turbine Pump‛units is also worth noting. These units can be used as turbine

while generating power and as pump while pumping water to storage. The

generator in this case works as motor during reverse operation. The efficiency

in such case is high and almost the same in both the operations. With the use

of reversible turbine pump sets, additional capital investment on pump and its

motor can be saved and the scheme can be worked more economically.

Pumped storage plants are employed at the places where the

quantity of water available for power generation is inadequate. Here the water

passing through the turbines is store in ‘tail race pond’During. low load

periods this water is pumped back to the head reservoir using the extra energy

available. This water can be again used for generating power during peak load

periods. Pumping of water may be done seasonally or daily depending upon the

conditions of the site and the nature of the load on the plant.

Related Topics