Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track and Track Stresses

Coning of Wheels

Coning of Wheels

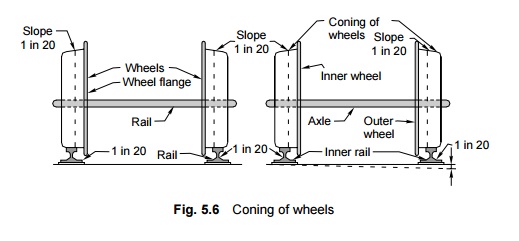

The

tread of the wheels of a railway vehicle is not made flat, but sloped like a

cone in order to enable the vehicle to move smoothly on curves as well as on

straight tracks. The wheels are generally centrally aligned on a straight and

level surface with uniform gauge, and the circumference of the treads of the

inner and outer wheels are equal as can be seen in Fig. 5.6.

The problem, however, arises in the case of a curve,

when the outer wheel has to negotiate more distance on the curve as compared to

the inner wheel. Due to the action of centrifugal force on a curve, the vehicle

tends to move out. To avoid this the circumference of the tread of the outer

wheel is made greater than that of the inner wheel. This helps the outer wheel

to travel a longer distance than the inner wheel.

The wheels of a railway vehicle are connected by an

axle, which in turn is fixed on a rigid frame. Due to the rigidity of the

frame, the rear axle has a tendency to move inward, which does not permit the

leading axle to take full advantage of the coning. The rigidity of the frame,

however, helps to bring the vehicle back into central alignment and thus works

as a balancing factor.

The coning of wheels helps to keep the vehicle

centrally aligned on a straight and level track also. Slight irregularities in

the track do occur as a result of moving loads and the vagaries of the weather.

The wheels, therefore, move from side to side and therefore the vehicles sway.

Due to the coning of wheels, this side movement results in the tread

circumference of one wheel increasing over the other. As both the wheels have

to traverse the same distance, this causes one wheel to slide. Due to the

resistance caused by the sliding, any further side movement is prevented. If

there was no coning, the side movement would have continued and the flange of

the wheel would have come in contact with the side of the rail, causing jerks

and making the ride uncomfortable.

Coning of wheels causes wear and tear due to the

slipping action. It is, however, useful as

(a)

it helps the vehicle to negotiate a

curve smoothly,

(b)

it provides a smooth ride, and

(c)

it reduces the wear and tear of the

wheel flanges.

As

far as the slip is concerned, it can be mathematically calculated as follows.

where ? is the angle at the centre of the curve fixed by the rigid wheel box

and G is the gauge in metres.

The approximate value of the slip for broad gauge is

0.029 metre per degree of the curve.

Related Topics