Chapter: Mechanical : Heat and Mass Transfer : Phase Change Heat Transfer and Heat Exchangers

Condensation-Filmwise and Dropwise

Condensation-Filmwise and Dropwise

Condensation

is the process of transition from a vapour to the liquid or solid state. The

process is accompanied by liberation of heat energy due to the change 10 phase.

When a vapour comes 10 contact with a surface maintained at a temperature lower

than the saturation temperature of the vapour corresponding to the pressure at

which it exists, the vapour condenses on the surface and the heat energy thus

released has to be removed. The efficiency of the condensing unit is determined

by the mode of condensation that takes place:

Filmwise

- the condensing vapour forms a continuous film covering the entire surface,

Dropwise - the vapour

condenses into small liquid droplets of various sizes. The dropwise

condensation has a much higher rate of heat transfer than filmwise condensation

because the condensate in dropwise condensation gets removed at a faster rate

leading to better heat transfer between the vapour and the bare surface. .

It is therefore

desirable to maintain a condition of dropwise condensation 1D commercial

application. Dropwise condensation can only occur either on highly polished

surfaces or on surfaces contaminated with certain chemicals. Filmwise

condensation is expected to occur in most instances because the formation of

dropwise condensation IS greatly influenced by the presence of non-condensable

gases, the nature and composition of surfaces and the velocity of vapour past

the surface.

Filmwise Condensation Mechanism on a

Vertical Plane Surface--

Assumption

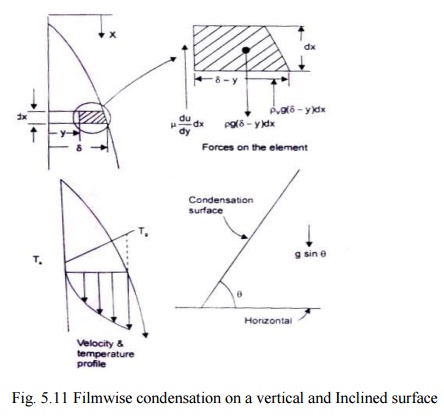

Let us consider a plane

vertical surface at a constant temperature, Ts on which a pure

vapour at saturation temperature, Tg (Tg > Ts)

is condensing. The coordinates are: X-axis along the plane surface wit~ its

origin at the top edge and Y-axis is normal to the plane surface as shown in Fig.

11.1. The condensing liquid would wet the solid surface, spread out and form a

continuous film over the entire condensing surface. It is further assumed that

(i) the continuous film

of liquid will flow downward (positive X-axis) under the action of gravity and

its thickness would increase as more and more vapour condenses at the liquid -

vapour interface,

Fig.

5.11 Filmwise condensation on a vertical and Inclined surface

(ii)

the continuous film so formed would

offer a thermal resistance between the vapour and the surface and would reduce

the heat transfer rates,

(iii) the

flow in the film would be laminar,

(iv)there

would be no shear stress exerted at the liquid vapour interface,

(v) the

temperature profile would be linear, and

(vi)

the weight of the liquid film would be

balanced by the viscous shear in the liquid film and the buoyant force due to

the displaced vapour.

An Expression for the Liquid Film

Thickness and the Heat Transfer Coefficient

Laminar

Filmwise Condensation on a Vertical Plate

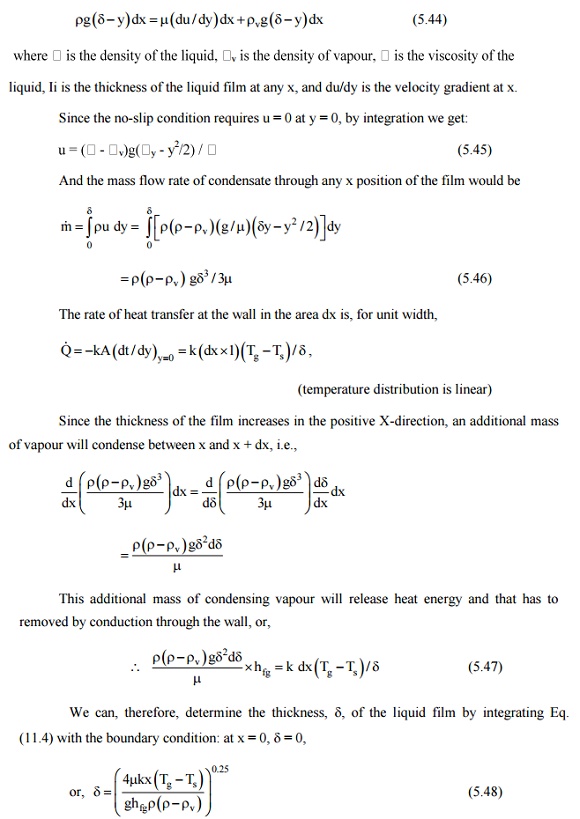

We

choose a small element, as shown in Fig. 11.1 and by making a force balance, we

Write

rg dy-dx

=dum/dy

dx g + ry dxd -

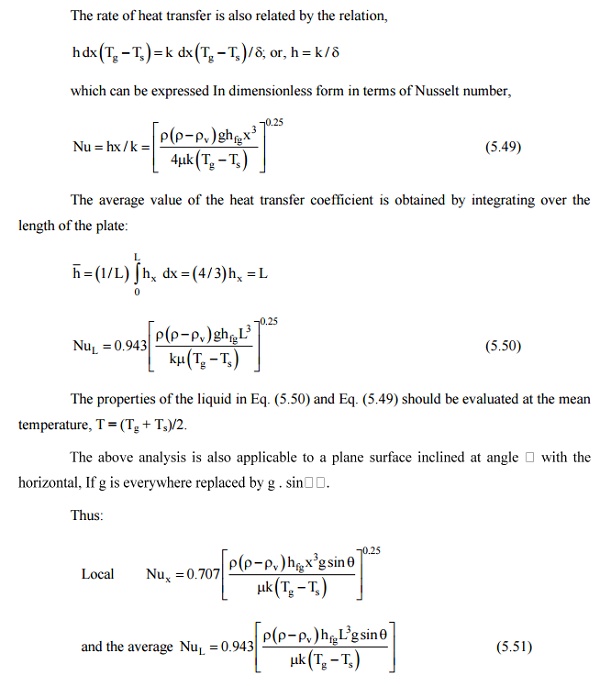

zero, (a horizontal surface) we would get an absurd

result. But these equations are valid for condensation on the outside surface

of vertical tubes as long as the curvature of the tube surface is not too

great.

Related Topics