Chapter: Mechanical : Heat and Mass Transfer : Phase Change Heat Transfer and Heat Exchangers

Classification of Heat Exchangers

Classification of Heat Exchangers

Heat exchangers are

generally classified according to the relative directions of hot and cold

fluids:

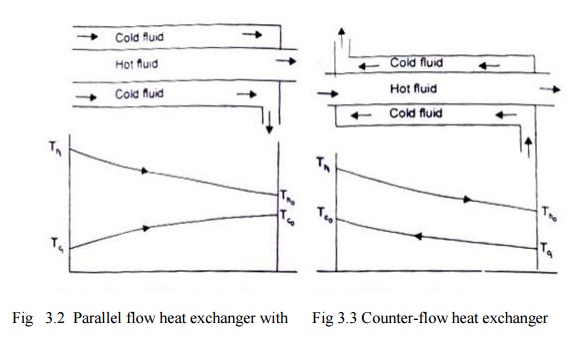

(a) Parallel

Flow –the hot and cold fluids flow in the same direction. Fig 3.2 depicts such

a heat exchanger where one fluid (say hot) flows through the pipe and the other

fluid (cold) flows

through the annulus.

(a) (b)

Counter Flow –the two fluids flow through the pipe but in opposite directions.

A common type of such a heat exchanger is shown in Fig. 3.3. By comparing the

temperature distribution of the two types of heat exchanger

Fig

3.2 Parallel flow heat exchanger with Fig

3.3 Counter-flow heat exchanger

temperature

distribution with

temperature distribution

we find that the

temperature difference between the two fluids is more uniform in counter flow

than in the parallel flow. Counter flow exchangers give the maximum heat

transfer rate and are the most favoured devices for heating or cooling of

fluids.

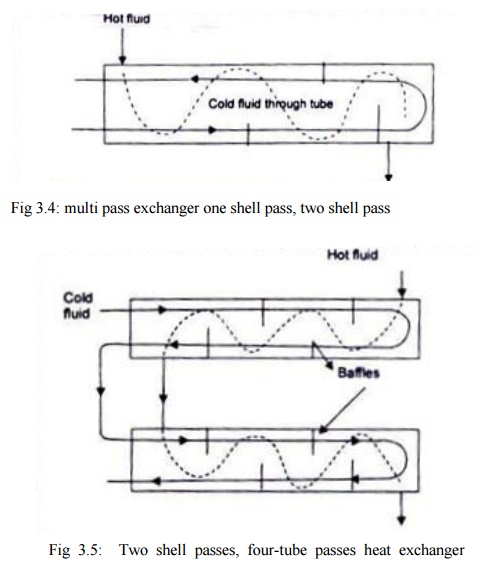

When the two fluids

flow through the heat exchanger only once, it is called one-shell-pass and

one-tube-pass as shown in Fig. 3.2 and 3.3. If the fluid flowing through the

tube makes one pass through half of the tube, reverses its direction of flow,

and makes a second pass through the remaining half of the tube, it is called

'one-shell-pass, two-tube-pass' heat exchanger,fig 3.4. Many other possible

flow arrangements exist and are being used. Fig. 10.5 depicts a

'two-shell-pass, four-tube-pass' exchanger.

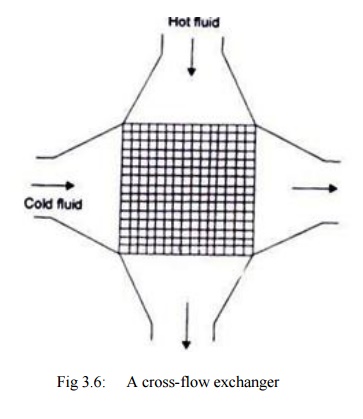

(b) Cross-flow

- A cross-flow heat exchanger has the two fluid streams flowing at right angles

to each other. Fig. 3.6 illustrates such an arrangement An automobile radiator

is a good example of cross-flow exchanger. These exchangers are 'mixed' or

'unmixed' depending upon the

mixing or not mixing of

either fluid in the direction transverse to the direction of the flow stream

and the analysis of this type of heat exchanger is extremely complex because of

the variation in the temperature of the fluid in and normal to the direction of

flow.

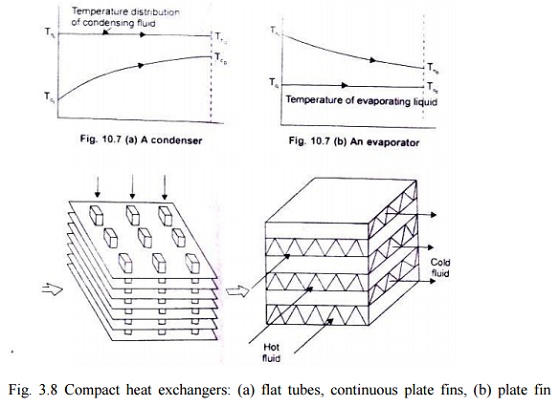

(d)

Condenser and Evaporator - In a

condenser, the condensing fluid temperature remains almost constant throughout

the exchanger and temperature of the colder fluid gradually increases from the

inlet to the exit, Fig. 3.7 (a). In an evaporator, the temperature of the hot

fluid gradually decreases from the inlet to the outlet whereas the temperature

of the colder fluid remains the same during the evaporation process, Fig.

3.7(b). Since the temperature of one of the fluids can be treated as constant,

it is immaterial whether the exchanger is parallel flow or counter flow.

(e)

Compact Heat Exchangers - these devices have close arrays of finned tubes or

plates and are typically used when atleast one of the fluids is a gas. The

tubes are either flat or circular as shown in Fig. 10.8 and the fins may be

flat or circular. Such heat exchangers are used to a chieve a very large (³700 m2/mJ) heat transfer surface area per

unit volume. Flow passages are typically small and the flow is usually laminar.

Fig

3.5: Two shell passes, four-tube passes heat exchanger (baffles increases the

convection coefficient of the shell side fluid by inducing turbulance and a

cross flow velocity component)

Fig

3.6: A cross-flow exchanger

Fig. 3.8 Compact heat

exchangers: (a) flat tubes, continuous plate fins, (b) plate fin (single pass)

Related Topics