Chapter: civil : Applied Hydraulic Engineering: Pumps

Centrifugal Pumps

Centrifugal Pumps

These are so called because energy is imparted to the fluid by

centrifugal action of moving blades from the inner radius to the outer radius.

The main components of centrifugal pumps are (1) the impeller, (2) the casing

and (3) the drive shaft with gland and packing.

Additionally suction pipe with one way valve (foot valve) and

delivery pipe with delivery valve completes the system.

The liquid enters the eye of the impeller axially due to the

suction created by the impeller motion. The impeller blades guide the fluid and

impart momentum to the fluid, which increases the total head (or pressure) of

the fluid, causing the fluid to flow out.

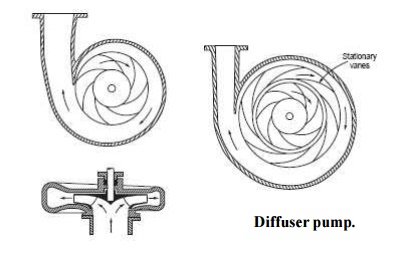

The fluid comes out at a high velocity which is not directly

usable. The casing can be of simple volute type or a diffuser can be used as

desired. The volute is a spiral casing of gradually increasing cross section. A

part of the kinetic energy in the fluid is converted to pressure in the casing.

Figure

shows a sectional view of the centrifugal pump.

1 Volute type centrifugal

pump.

Gland and packing or so called stuffing box is used to reduce

leakage along the drive shaft. By the use of the volute only a small fraction

of the kinetic head can be recovered as useful static head.

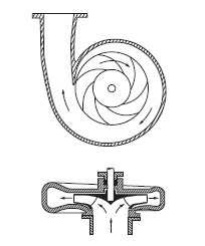

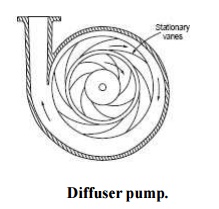

A

diffuser can diffuse the flow more efficiently and recover kinetic head as

useful static head. A view of such arrangement is shown in figure Diffuser pump

are also called as turbine pumps as these resembles Francis turbine with flow

direction reversed.

2

Impeller

The impeller consists of a disc with blades mounted

perpendicularly on its surface. The blades may of three different orientations.

These are

(i) Radial, (ii) Backward curved, and (iii) Forward

curved.

Backward

and forward refers to the direction of motion of the disc periphery. Of these

the most popular one is the backward curved type, due to its desirable characteristics,

which reference to the static head

developed and power

variation with flow rate.

A simple disc

with blades mounted perpendicularly on it is

called open impeller. If another

disc is used to cover the blades, this type is called shrouded impeller. This

is more popular with water pumps. Open impellers are well adopted for use with

dirty or water containing solids. The third type is just the blades spreading

out from the shaft.

These are used to pump slurries. Impellers may be of cast iron

or bronzes or steel or special alloys as required by the application. In order

to maintain constant radial velocity, the width of the impeller will be wider

at entrance and narrower at the exit. The blades are generally cast integral

with the disc. Recently even plastic material is used for the impeller. To

start delivery of the fluid the casing and impeller should be filled with the

fluid without any air pockets. This is called priming.

If air is present the there will be only compression and no

delivery of fluid. In order to release any air entrained an air valve is

generally provided

The one

way foot value keeps the suction line and the pump casing filled with water.

3 Classification

As already mentioned, centrifugal pumps may be classified in

several ways. On the basis of speed as low speed, medium speed and high speed

pumps.

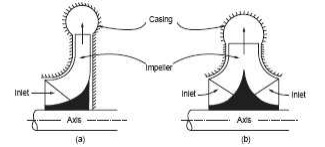

On the basis of direction of flow of fluid, the classification

is radial flow, mixed flow and radial flow. On the basis of head pumps may be

classified as low head (10 m and below), medium head (10-50 m) and high head

pumps.

Single

entry type and double entry type is another classification. Double entry pumps

have blades on

both sides of

the impeller disc.

This leads to reduction in axial thrust and increase in flow for the

same speed and diameter.

When the

head required is high and which cannot

be developed by

a single impeller, multi

staging is used.

In deep well

submersible pumps the diameter is limited by the diameter of the

bore well casing. In this case multi stage pump becomes a must. In multi stage

pumps several impellers are mounted on the same shaft and the outlet flow of

one impeller is led to the inlet of the next impeller and so on. The total head

developed equals the sum of heads developed by all the stages.

4 Single

and double entry pumps

Pumps may also be operated in parallel to obtain

large volumes of flow. The characteristics under series and parallel operations

are discussed later in the chapter. The classification may also be based on the

specific speed of the pump. the dimensionless parameters have

been derived in the case of hydraulic machines. The same is also repeated in

example.

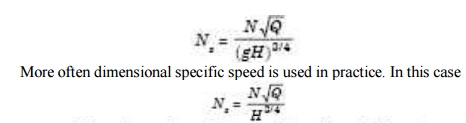

The

expression for the dimensionless specific speed is given in equation

5 Pressure Developed By

The Impeller

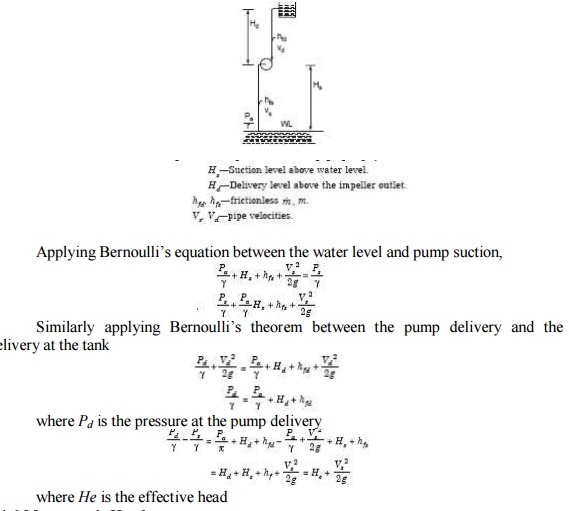

The

general arrangement of a centrifugal pump system is shown in Figure

where He

is the effective head

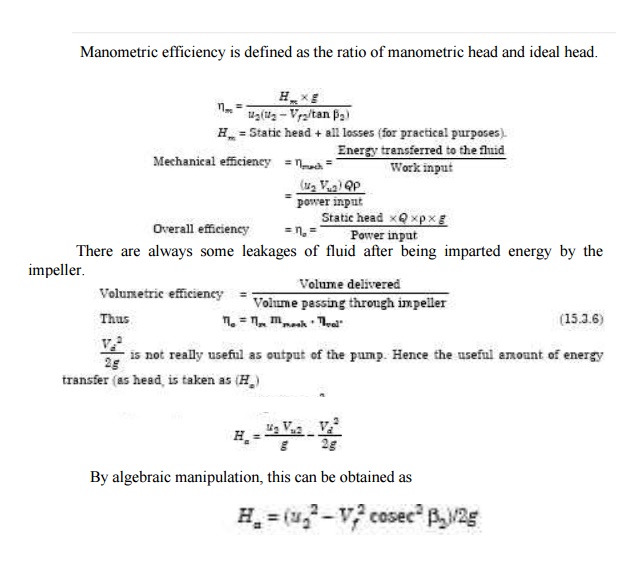

6 Manometric Head

The official code defines the head on the pump as the

difference in total energy heads at the suction and delivery flanges. This head

is defined as manometric head.

The total

energy at suction inlet (expressed as head of fluid)

F/r + V2/2g + Zs

where Zs

is the height of suction gauge from datum. The total energy at the delivery of

the pump

F/r + V2/2g + Zs

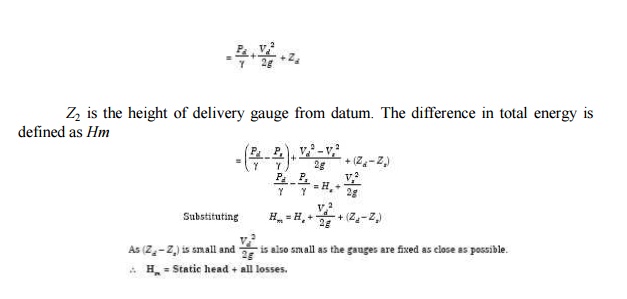

Z2 is the

height of delivery gauge from datum. The difference in total energy is defined

as Hm

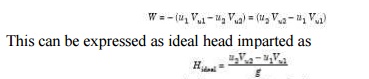

7 Energy Transfer By

Impeller

The

energy transfer is given by Euler Turbine equation applied to work absorbing

machines,

The

velocity diagrams at inlet and outlet of a backward curved vaned impeller is

shown in figure The inlet whirl is generally zero. There are no guide vanes at

inlet to impart whirl. So the inlet triangle is right angled.

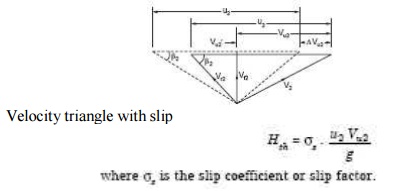

8 Slip and Slip Factor

In the analysis it is assumed that all the fluid between two

blade passages have the same velocity (both magnitude of direction). Actually

at the leading edge the pressure is higher and velocity is lower. On the

trailing edge the pressure is lower and the velocity is higher. This leads to a

circulation over the blades. Causing a non uniform velocity distribution.

The

average angle at which the fluid leaves the blade is less than the blades

angle. The result is a reduction in the exit whirl velocity Vu2. This is

illustrated in the following figure. The solid lines represent the velocity

diagram without slip. The angle ?2 is the

blade angle. The dotted lines represent the velocity diagram after slip. The

angle

?2? < ?2. It may

be seen that Vu2? < Vu2. The ratio Vu2?/Vu2

is known as slip factor. The result of the slip is that the energy transfer to

the fluid is less than the theoretical value.

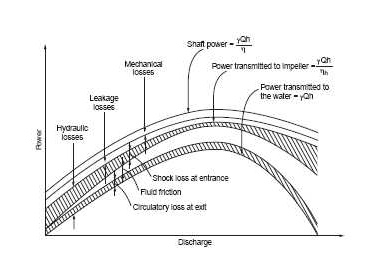

9 Losses

in Centrifugal Pumps

Mainly

there are three specific losses which can be separately calculated. These are

10 Losses in pump

(i) Mechanical friction losses between the fixed and

rotating parts in the bearings and gland and packing.

(ii)

Disc friction loss between the impeller surfaces and the fluid.

(iii)

Leakage and recirculation losses. The recirculation is along the clearance

between the impeller and the casing due to the pressure difference between the

hub and tip of the impeller. The various losses are indicated in figure.

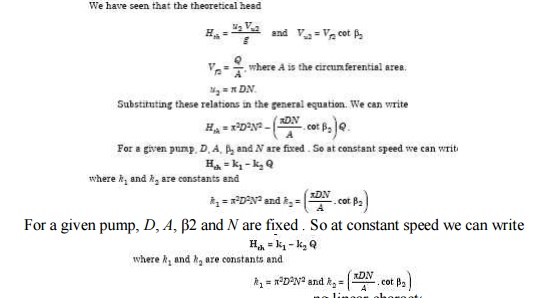

11 Pump

Characteristics

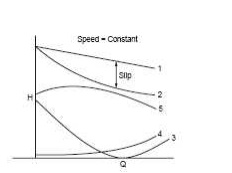

Hence at constant speed this leads to a drooping linear

characteristics for backward curved blading. This is shown by curve 1 in Figure

15.4.1. The slip causes drop in the head, which can be written as ? Vu2

u2/g. As flow increases this loss also increases.

Curve 2

shown the head after slip. The flow will enter without shock only at the design

flow rate. At other flow rates, the water will enter with shock causing losses.

This lose

can be expressed as hshock =

k3 (Qth - Q)2

The

reduced head after shock losses is shown in curve 5. The shock losses with flow

rate is shown by curve 3. The mechanical losses can be represented by hf = k4

Q2. The variation is shown by curve 4. With variation of speed the head

characteristic is shifted near paralley with the curve 5 shown in Figure.

12 Characteristics of a

centrifugal pump

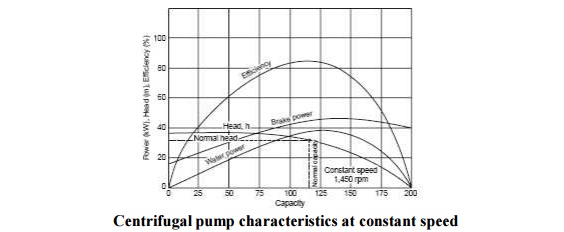

The

characteristic of a centrifugal pump at constant speed is shown in Figure. It

may be noted that the power increases and decreases after the rated capacity.

In this way the pump is self limiting in power and the choice of the motor is

made easy. The distance between the brake power and water power curves gives

the losses.

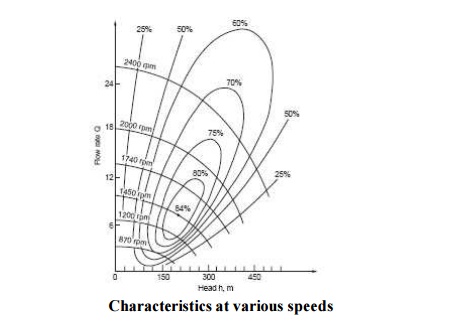

The

pump characteristics at various speeds including efficiency contours in shown

in Figure. Such a plot helps in the development of a pump, particularly in

specifying the head and flow rates.

Related Topics