Chapter: Mechanical : Advanced IC Engines : Engine Exhaust Emission Control

Catalytic convertor

Catalytic convertor:

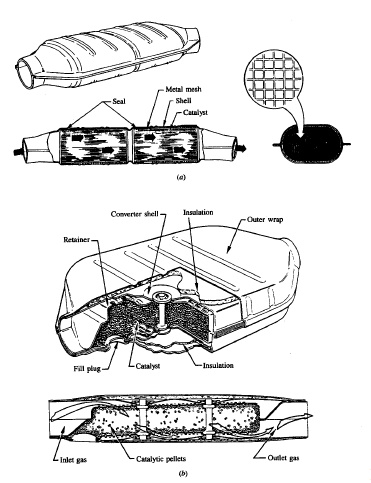

The

catalytic converters used in spark-ignition engines consist of an active

catalytic material in a specially designed metal casing which directs the

exhaust gas flow through the catalyst bed. The active material employed for CO

and HC oxidation or NO reduction (normally noble metals, though base metals

oxidescan be used) must be distributed over a large surface area so that the

mass transfer characteristics between the gas phase and the active catalyst

surface are sufficient to allow close to 100 percent conversion with high

catalytic activity. The two configurations commonly used are shown in Fig.

11-53. One systememploys a ceramic honeycomb structure or monolith held in a

metal can in theexhaust stream. The active (noble metal) catalyst material is

impregnated into ahighly porous alumina washcoat about 20 pm thick that is

applied to the passagewaywalls. The typical monolith has square-cross-section

passageways with inside dimensions of @1 mm

separated by thin (0.15 to 0.3 mm)

porous walls.

The

number of passageways per square centimetre varies between about 30 and60. The

washcoat, 5 to 15 percent of the weight of the monolith, has a surfacearea of

100 to 200 m2/g. The other converter design uses a bed of sphericalceramic

pellets to provide a large surface area in contact with the flow. With

pellet

catalysts, the noble metal catalyst is impregnated into the highly

poroussurface of the spherical alumina pellets (typically 3 mm diameter) to a

depth ofabout 250 pm. The pellet material is chosen to have good crush and

abrasion resistance after exposure to temperatures of order 1000•C. The gas

flow is directed down through the bed as shown to provide a large flow area and

low pressure drop. The gas flow is turbu lent which results in high

mass-transfer rates; in the monolith catalyst passageways, it is laminar.

Related Topics