Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Burning of Bricks

Burning of Bricks

The burning of clay may be divided into three main stages.

Dehydration (400-650 o C):

This is also known as water smoking stage. During dehydration,

Oxidation Period (650-900 o C):

During the oxidation period, (1) remainder of carbon is eliminated and,

(2) the

ferrous iron is oxidized to the ferric form. The removal of sulphur is

completed only after the carbon has been eliminated. Sulphur on account of its

affinity for oxygen, also holds back the oxidation of iron. Consequently, in

order to avoid black or spongy cores, oxidation must proceed at such a rate

which will allow these changes to occur before the heat becomes sufficient to

soften the clay and close its pore. Sand is often added to the raw clay to

produce a more open structure and thus provide escape of gases generated in

burning.

Vitrification-To

convert the mass into glass like substance - the

temperature ranges from 900- 1100 o C

for low melting clay and 1000-1250 o C for high melting

clay. Great care is required in cooling the bricks below the cherry red heat in

order to avoid checking and cracking. Vitrification period may further be

divided into (a) incipient vitrification, at which the clay has softened

sufficiently to cause adherence but not enough to close the pores or cause loss

of space-on cooling

the material cannot be scratched by the knife; (b) complete vitrification, more

or less well-marked by maximum shrinkage; (c) viscous vitrification, produced

by a further increase in temperature which results in a soft molten mass, a

gradual loss in shape, and a glassy structure after cooling. Generally, clay

products are vitrified to the point of viscosity. However, paving bricks are

burnt to the stage of complete vitrification to achieve maximum hardness as

well as toughness.

Burning of bricks is done in a

clamp or kiln. A clamp is a temporary structure whereas kiln is a permanent

one.

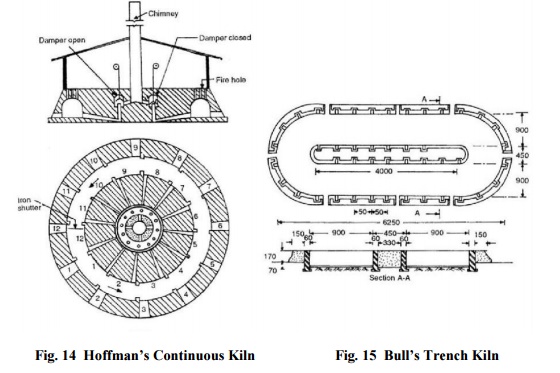

Burning in Clamp or Pazawah: A typical

clamp is shown in Fig. 2.9. The bricks and fuel are placed in alternate

layers. The amount of fuel is reduced successively in the top layers. Each

brick tier consists of 4-5 layers of bricks. Some space is

left between bricks for free circulation of hot gasses. After 30 per cent

loading of the clamp, the fuel in the lowest layer is fired and the remaining

loading of bricks and fuel is carried out hurriedly. The top and sides of the

clamp are plastered with mud. Then a coat of cowdung is given, which prevents

the escape of heat. The production of bricks is 2-3 lacs

and the process is completed in six months. This process yields about 60 per

cent first class bricks.

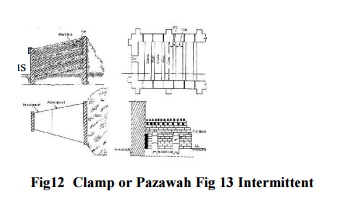

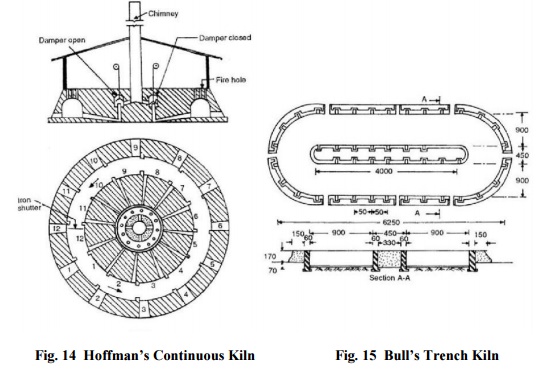

Kiln

Burning: The kiln used for burning bricks may be underground, e.g.

Bull's trench kiln or overground, e.g. Hoffman's kiln. These may be

rectangular, circular or oval in shape. When the process of burning bricks is

continuous, the kiln is known as continuous kiln, e.g. Bull's trench and

Hoffman's kilns.

On the other hand if the process of burning bricks

is discontinuous, the kiln is known as intermittent kiln. Intermittent Kiln:

The example of this type of an over ground, rectangular kiln is shown in Fig.

2.10. After loading the kiln, it is fired, cooled and

Kiln

unloaded and then the next loading is done. Since

the walls and sides get cooled during reloading and are to be heated again

during next firing, there is wastage of fuel.

Continuous Kiln: The

examples of continuous kiln are Hoffman's kiln (Fig. 2.11) and Bull's trench

kiln (Fig. 2.12). In a continuous kiln, bricks are stacked in various

chambers wherein the bricks undergo different treatments at the same time. When

the bricks in one of the chambers is fired, the bricks in the next set of

chambers are dried and preheated while bricks in the other set of chambers are

loaded and in the last are cooled.

Note: In

the areas where black cotton soil occur, a more elaborate method of processing

is

followed. The clay, which may be black or a

mixture of black and yellow, is first washed free of the

lime kankar in the 'GHOL' tanks. The slurry is then run off to the setting

tanks. After 3-4

days when the clay has settled down, the

supernatant water is bucketed off. Opening material like powdered grog of fine

coal ash (passing 2.00 mm sieve), which opens up the texture of clay mass, is

then added in predetermined proportions. This is usually 30 to 40 per cent of

the mass of clay. A solution of 0.5 per cent sodium chloride may also be added

at this stage to prevent lime bursting. The clay is then thoroughly mixed with

the opening materials added and allowed to dry further for a period of 3-4 days

till the mix attains the correct moulding consistency. Grog is prepared by

lightly calcining lumps of black cotton soil (about 10 to 15 cm dia.) in a

clamp at about 700 o to 750 o C. Coal ash, fire wood, brambles, etc. may be used

as fuel. The fuel and clay lumps are arranged in alternate layers in the clamp.

After calcination the clay is pulverized in a machine, such as disintegrator, a

hammer mill or a pan-mill to a fineness of less than 2.0 mm.

Related Topics