Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Bricks Tempering

Manufacturing Of Bricks

Tempering:

Tempering: Tempering consists of kneading

the earth with feet so as to make the mass stiff and plastics (by

plasticity, we mean the property which wet clay has of being permanently

deformed without cracking). It should preferably be carried out by storing the

soil in a cool place in layers of about 30 cm thickness for not less than 36

hours. This will ensure homogeneity in the mass

of clay for subsequent processing. For

manufacturing good brick, tempering is done in pug mills and the operation is

called pugging.

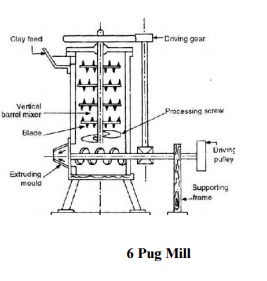

Pug mill

consists of a conical iron tube as shown in Fig. 6. The mill is sunk 60 cm into

the earth. A vertical shaft, with a number of horizontal arms fitted with

knives, is provided at the centre of the tube. This central shaft is rotated

with the help of bullocks yoked at the end of long arms. However, steam, diesel

or electric power may be used for this purpose. Blended earth along with

required water, is fed into the pug mill from the top. The knives cut through

the clay and break all the clods or lump-clays when the shaft rotates. The

thoroughly pugged clay is then taken out from opening provided in the side near

the bottom. The yield from a pug mill is about 1500 bricks.

Related Topics