Chapter: Civil : Construction Materials: Stones, Bricks,Concrete Blocks

Bricks Drying

Manufacturing Of Bricks

Drying

Green bricks contain about 7 - 30% moisture

depending upon the method of manufacture. Theobject of drying is to remove the

moistre to controlthe shrinkage and save fuel and time during burning.The

drying shrinkage is dependent upon pore spaceswithin the clay and the mixing

water. The additionof sand or ground burnt clay reduces shrinkage,increases

porosity and facilities drying. The moisturecontent is brought down to about 3

per cent underexposed conditions within three to four days. Thus,the strength

of the green bricks is increased and the bricks can be handled safely. Clay

products can be dried in open air driers or in artificial driers. The

artificial driers are of two types, the hot floor drier and the tunnel drier.

In the former, heat is applied by a furnance placed at one end of the drier or

by exhaust steam from the engine used to furnish power and is used for fire

bricks, clay pipes and terracotta. Tunnel driers are heated by fuels

underneath, by steam pipes, or by hot air from cooling kilns. They are more

economical than floor driers. In artificial driers, temperature rarely exceeds

120 o C. The time varies from one to three days. In developing countries, bricks

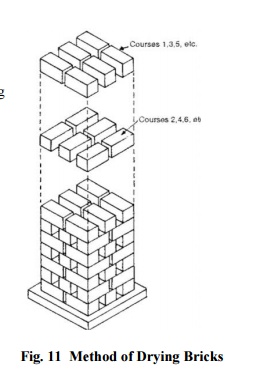

are normally dried in natural open air driers (Fig. 11). They are stacked on

raised ground and are protected from bad weather and direct sunlight. A gap of

about 1.0 m is left in the adjacent layers of the stacks so as to allow free

movement for the workers.

Related Topics