Production, Steps, Applications - Biogas Production | 11th Microbiology : Chapter 9 : Environmental Microbiology

Chapter: 11th Microbiology : Chapter 9 : Environmental Microbiology

Biogas Production

Biogas Production

Worldwide energy consumption and demand are growing up since

past 50 years. With the growth of population, demand for energy is also

increasing leading to an uneven supply and distribution of resources.

Therefore, the requirement of sustainable and eco friendly energy in India to

satisfy the energy demand is inevitable. Along with the source of sustainable

green energy, biogas production is an alternative way to produce clean energy

through solid waste management.

Biogas is a type of renewable energy that can be produced from

decomposition of animal and plant waste. It is composed of 50– 75% methane,

25–50% carbon dioxide, 0–10% nitrogen, 0–3% hydrogen sulphide, 0–1% hydrogen

and traces of other gases. The term “anaerobic” suggests that the process

occurs in the absence of free oxygen and produces CH4 through

decomposition of waste in nature and reduces environmental pollution.

Biogas generating technology is a favorable dual purpose

technology at present since used as fuel and fertiliser.

Leftover foods fruit & vegetable wastes and cow dung can be subjected to anaerobic digestion for energy production in a variety of ways.

Production of Biogas

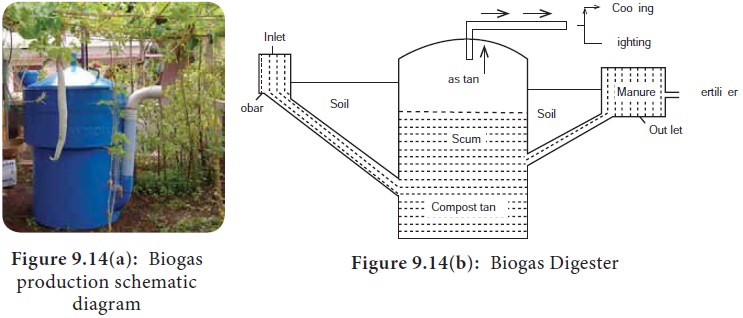

Biogas production is carried out in an airtight cylindrical tank

called biogas digester Cow dung is mixed with equal volume of water and made

into slurry and fed through the inlet of the biogas unit. The digestion

proceeds at 37°C with sufficent amount of nitrogen and phosphorus. The

production of biogas sets around 40-50 days, under anaerobic conditions.

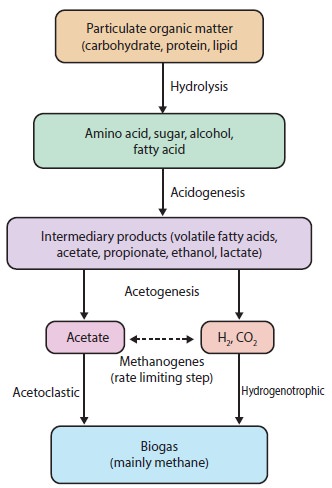

Production of biogas accomplished in 3 stages namely Hydrolysis, Acetogenesis

and Methanogenesis

Steps

Hydrolytic fermentative stage

In this step, several microbes secrete different enzymes, which

cleave the complex macromolecules into simpler forms. Organisms that are active

in a biogas process during the hydrolysis of polysaccharides include various

bacterial groups such as Bacillus, Clostridium, Cellulomonas.

Acetogenic stage

Through various fermentation reactions, the products from

hydrolysis are converted mainly into various organic acids (acetic acid,

propionic acid, butyric acid, succinic acid, lactic acid), alcohols, ammonia

(from amino acids), carbon dioxide and hydrogen. Facultative anaerobes and

hydrogen producing bacteria Example: Acetovibrio

cellulosolvens, Bacteroid cellulosolvens are involved.

Methanogenic stage

In this step, obligate anaerobic methane producing bacteria produce Methane gas as the major end product

along with Carbon dioxide, Hydrogen and traces of other gases. Methanogenesis

has six major pathways, each converting a different substrate into Methane gas.

The six major substrates used are Carbon dioxide, Formic acid, Acetic acid,

Methanol, Methylamine, and Dimethyl sulphate. The methanogenic bacteria include

Methanococcus voltae and Methanobacterium formicum (Figure 9.14

a, b).

Small scale biogas unit

The biogas production is carried out in an air tight cylindrical tank called biogas digester (Figure9.15).

Applications

· Biogas used as fuel

·

Used to generate electricity

·

Biogas is used to run any type of heat engine in order to generate

electrical and mechanical power.

·

Producing high quality fertilizer.

·

Reducing water and air pollution.

Related Topics