Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Introduction

Automation in Production Systems

AUTOMATION IN PRODUCTION SYSTEMS

Some

elements of the firm’s production system are likely to be automated, whereas

others will be operated manually or clerically. For our purposes here, automation can be defined as a

technology concerned with the application of mechanical, electronic, and

computerbased systems to operate and control production.

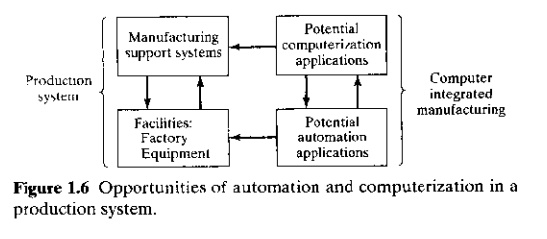

The

automated elements of the production system can be separated into two

categories: (1) automation of the manufacturing systems in the factory and (2)

computerization of the manufacturing support systems. In modern production

systems, the two categories overlap to some extent, because the automated

manufacturing systems operating on the factory floor are themselves often

implemented by computer systems and connected to the computerized manufacturing

support systems and management information system operating at the plant and

enterprise levels. The term computerintegrated manufacturing is used to

indicate this extensive use of computers in production systems. The two

categories of automation are shown in Figure 1.6 as an overlay on Figure 1.1.

1.Automated

Manufacturing Systems

Automated

manufacturing systems operate in the factory on the physical product.They

perform operations such as processing, assembly, inspection, or material

handling, in some cases accomplishing more than one of these operations in the

same system.They are called automated because they perform their operations

with a reduced level of human participation compared with the corresponding

manual process. In some highly automated systems, there is virtually no human

participation. Examples of automated manufacturing systems include:

• automated

machine tools that process parts

• transfer

lines that perform a series of machining operations

• automated

assembly systems

• manufacturing

systems that use industrial robots to perform processing or assembly operations

• automatic

material handling and storage systems to integrate manufacturing operations

• automatic

inspection systems for quality control

Automated

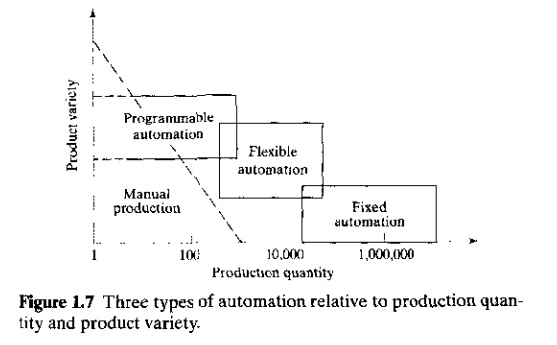

manufacturing systems can be classified into three basic types (for our

purposes in this introduction; we explore the topic of automation in greater

depth in Chapter 3):

(1) fixed

automation, (2) programmable automation, and (3) flexible automation.

Fixed

Automation. Fixed

automation is a system in which the sequence

of processing (or assembly) operations is fixed by the equipment configuration.

Each of the operations in the sequence is usually simple, involving perhaps a

plain linear or rotational motion or an uncomplicated combination of the two;

for example, the feeding of a rotating spindle. It is the integration and

coordination of many such operations into one piece of equipment that makes the

system complex. Typical features of fixed automation are:

• high

initial investment for customengineered equipment

• high

production rates

• relatively

inflexible in accommodating product variety

The

economic justification for fixed automation is found in products that are

produced in very large quantities and at high production rates. The high

initial cost of the equipment can be spread over a very large number of units,

thus making the unit cost attractive com pared with alternative methods of

production. Examples of fixed automation include machining transfer lines and

automated assembly machines.

Programmable

Automation. In programmable

automation, the production equipment is designed with the capability to change the

sequence of operations to accommodate different product configurations. The

operation sequence is controlled by a program,

which is a set of instructions coded so that they can be read and interpreted

by the system. New programs can be prepared and entered into the equipment to

produce new products. Some of the features that characterize programmable

automation include:

• high

investment in general purpose equipment

• lower

production rates than fixed automation

• flexibility

to deal with variations and changes in product configuration

• most

suitable for batch production

Programmable

automated production systems are used in low and mediumvolume production. The

parts or products are typically made in batches. To produce each new batch of a

different product, the system must be reprogrammed with the set of machine

instructions that correspond to the new product. The physical setup of the

machine must also be changed: Tools must be loaded, fixtures must be attached

to the machine table, and the required machine settings must be entered. This

changeover procedure takes time. Consequently, the typical cycle for a given

product includes a period during which the setup and reprogramming takes place,

followed by a period in which the batch is produced. Examples of programmable

automation include numerically controlled (NC) machine tools, industrial

robots, and programmable logic controllers.

Flexible

Automation. Flexible

automation is an extension of programmable

automation. A flexible automated system is capable of producing a variety of

parts (or products) with virtually no time lost for changeovers from one part

style to the next. There is no lost production time while reprogramming the

system and altering the physical setup (tooling, fixtures, machine settings).

Consequently, the system can produce various combinations and schedules of

parts or products instead of requiring that they be made in batches. What makes

flexible automation possible is that the differences between parts processed by

the system are not significant. It is a case of soft variety, so that the

amount of changeover required between styles is minimal. The features of

flexible automation can be summarized as follows:

• high

investment for a customengineered system

• continuous

production of variable mixtures of products

• medium

production rates

• flexibility

to deal with product design variations

Examples

of flexible automation are the flexible manufacturing systems for performing

machining operations that date back to the late 1960s.

The

relative positions of the three types of automation for different production

volumes and product varieties are depicted in Figure 1.7. For low production

quantities and new product introductions, manual production is competitive with

programmable automation, as we indicate in the figure and discuss in Section

1.4.1.

2. Computerized

Manufacturing Support Systems

Automation

of the manufacturing support systems is aimed at reducing the amount of manual

and clerical effort in product design, manufacturing planning and control, and

the business functions of the firm. Nearly all modern manufacturing support

systems are implemented using computer systems. Indeed, computer technology is

used to implement automation of the manufacturing systems in the factory as

well. The term computer— integrated manufacturing (CIM) denotes

the pervasive use of computer systems to design the products, plan the production, control the operations, and

perform the various business—related functions needed in a manufacturing firm.

True CIM involves integrating all of these functions in one system that

operates throughout the enterprise. Other terms are used to identify specific

elements of the CIM system. For example, computeraided

design (CAD) denotes the use of

computer systems to support the product design function. Computeraided manufacturing (CAM) denotes the use of computer

systems to perform functions related to manufacturing engineering, such as

process planning and numerical control part programming. Some computer systems

perform both CAD and CAM, and so the term CAD/CAM

is used to indicate the integration of the two into one system.

Computer—integrated manufacturing includes CAD/CAM, but it also includes the

firm’s business functions that are related to manufacturing.

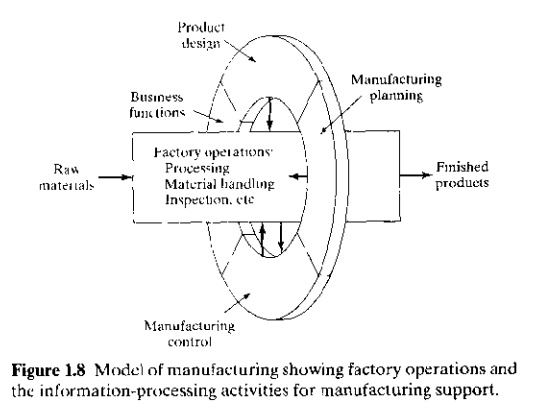

Let us

attempt to define the relationship between automation and CIM by developing a

conceptual model of manufacturing. In a manufacturing firm, the physical

production activities that take place in the factory can be distinguished from

the information—processing activities, such as product design and production

planning, that usually occur in an office environment. The physical activities

include all of the processing, assembly, material handling, and inspection

operations that are performed on the product in the factory. These operations

come in direct contact with the product during manufacture. The relationship

between the physical activities and the information—processing activities in our

model is depicted in Figure 1.8. Raw materials flow into one end of the factory

and finished products flow out the other end. The physical activities take

place inside the factory. In our model, the information—processing activities

form a ring that surrounds the factory, providing the data and knowledge

required to successfully produce the product. These in

formation—processing

activities are accomplished to implement the four basic manufacturing support

functions identified earlier: (1) business functions, (2) product design, (3)

manufacturing planning, and (4) manufacturing control. These four functions

form a cycle of events that must accompany the physical production activities

but do not directly touch the product.

3. Reasons

for Automating

Companies

undertake projects in manufacturing automation and computerintegrated

manufacturing for a variety of good reasons. Some of the reasons used to

justify automation are the following:

1. To increase labor productivity.

Automating a manufacturing operation usually increases production rate and

labor productivity. This means greater output per hour of labor input.

2. To reduce labor cost.

Everincreasing labor cost has been and continues to be the trend in the world’s industrialized societies. Consequently,

higher investment in automation has become economically justifiable to replace

manual operations. Machines are increasingly being substituted for human labor

to reduce unit product cost.

3. To mitigate the effects of labor shortages. There

is a general shortage of labor in many advanced

nations, and this has stimulated the development of automated operations as a

substitute for labor.

4. To reduce or eliminate routine manual and clerical tasks. An argument can be put forth that there is social value in automating operations that are routine, boring, fatiguing, and possibly irksome. Automating such tasks serves a purpose of improving the general level of working conditions.

To improve worker safety. By automating a given operation and transferring the worker from active participation in the process to a supervisory role, the work is made safer. The safety and physical wellbeing of the worker has become a national objective with the enactment of the Occupational Safety and Health Act (OSHA) in 1970. This has provided an impetus for automation.

6. To improve product quality.

Automation not only results in higher production rates than manual operations; it also performs the manufacturing process

with greater uniformity and conformity to quality specifications. Reduction of

fraction defect rate is one of the chief benefits of automation.

7. To reduce manufacturing lead time.

Automation helps to reduce the elapsed time between customer order and product

delivery, providing a competitive advantage to the manufacturer for future

orders. By reducing manufacturing lead time, the manufacturer also reduces

workinprocess inventory.

8. To accomplish processes that cannot be done

manually. Certain operations cannot be accomplished

without the aid of a machine. These processes have requirements for precision,

miniaturization, or complexity of geometry, that cannot be achieved manually.

Examples include certain integrated circuit fabrication operations, rapid

prototyping processes based on computer graphics (CAD) models, and the

machining of complex, mathematically defined surfaces using computer numerical

control. These processes can only be realized by computer controlled systems.

9. To avoid the high cost of not automating. There

is a significant competitive advantage gained in automating a manufacturing

plant. The advantage cannot easily be demonstrated on a company’s project

authorization form. The benefits of automation often show up in unexpected and

intangible ways, such as in improved quality, higher sales, better labor

relations, and better company image. Companies that do not automate are likely

to find themselves at a competitive disadvantage with their customers, their

employees, and the general public.

Related Topics