Chapter: Mechanical : Automobile Engineering : Transmission Systems

Automatic Transmission

Automatic Transmission:

An automatic transmission (commonly "AT" or

"Auto") is an automobile gearbox that can change gear ratios

automatically as the vehicle moves, freeing the driver from having to shift

gears manually.

Automatic Transmission Modes:

In order to select the mode, the driver would have to move a

gear shift lever located on the steering column or on the floor next to

him/her. In order to select gears/modes the driver must push a button in

(called the shift lock button) or pull the handle (only on column mounted

shifters) out. In some vehicles position selector buttons for each mode on the

cockpit instead, freeing up space on the central console. Vehicles conforming

to U.S. Government standards must have the modes ordered P-R-N-D-L (left to

right, top to bottom, or clockwise). Prior to this, quadrant-selected automatic

transmissions often utilized a P-N-D-L-R layout, or similar. Such a pattern led

to a number of deaths and injuries owing to un-intentional gear miss-selection,

as well the danger of having a selector (when worn) jump into Reverse from Low

gear during engine braking maneuvers.

Automatic Transmissions have various modes depending on the

model and make of the transmission. Some of the common modes are:

Park Mode (P):-

This selection mechanically locks the transmission,

restricting the car from moving in any direction. A parking pawl prevents the

transmission—and therefore the vehicle—from

moving, although the vehicle's non-drive wheels may still spin freely. For this

reason, it is recommended to use the hand brake (or parking brake) because this

actually locks the (in most cases, rear) wheels and prevents them from moving.

This also increases the life of the transmission and the park pin mechanism,

because parking on an incline with the transmission in park without the parking

brake engaged will cause undue stress on the parking pin. An

efficiently-adjusted hand brake should also prevent the car from moving if a

worn selector accidentally drops into reverse gear during early morning

fast-idle engine warm ups.

Reverse (R):-

This puts the car into the reverse gear, giving the ability

for the car to drive backwards. In order for the driver to select reverse they

must come to a complete stop, push the shift lock button in (or pull the shift

lever forward in the case of a column shifter) and select reverse. Not coming

to a complete stop can cause severe damage to the transmission. Many modern

automatic gearboxes have a safety mechanism in place, which does to some extent

prevent (but doesn't completely avoid) inadvertently putting the car in reverse

when the vehicle is moving.

This mechanism usually consists of a solenoid-controlled

physical barrier on either side of the Reverse position, which is

electronically engaged by a switch on the brake pedal. Therefore, the brake

pedal needs to be depressed in order to allow the selection of reverse. Some

electronic transmissions prevent or delay engagement of reverse gear altogether

while the car is moving.

Neutral/No gear (N):-

This disconnects the transmission from the wheels so the car

can move freely under its own weight. This is the only other selection in which

the car can be started.

Drive (D):-

This allows the car to move forward and accelerate through its

range of gears. The number of gears a transmission has depends on the model,

but they can commonly range from 3, 4 (the most common), 5, 6 (found in VW/Audi

Direct Shift Gearbox), 7 (found in Mercedes 7G gearboxes, BMW M5 and VW/Audi

Direct Shift Gearbox) and 8 in the newer models of Lexus cars. Some cars when

put into D will automatically lock the doors or turn on the Daytime Running

Lamps.

Overdrive ([D], Od, Or A Boxed

D):-

This mode is used in some transmissions to allow early

Computer Controlled Transmissions to engage the Automatic Overdrive. In these

transmissions, Drive (D) locks the Automatic Overdrive off, but is identical

otherwise. OD (Overdrive) in these cars is engaged under steady speeds or low

acceleration at approximately 35-45 mph (approx. 72 km/h). Under hard

acceleration or below 35-45 mph, the transmission will automatically downshift.

Vehicles with this option should be driven in this mode unless circumstances

require a lower gear.

Second (2 or S):-

This mode limits the transmission to the first two gears, or

more commonly locks the transmission in second gear. This can be used to drive

in adverse conditions such as snow and ice, as well as climbing or going down

hills in the winter time. Some vehicles will automatically up-shift out of

second gear in this mode if a certain rpm range is reached, to prevent engine

damage.

First (1 or L):-

This mode locks the transmission in first gear only. It will

not accelerate through any gear range. This, like second, can be used during

the winter season, or for towing.

As well as the above modes there are also other modes,

dependent on the manufacturer and model. Some examples include:

D5:- In Hondas and Acuras equipped with 5-speed automatic

transmissions, this mode is used commonly for highway use (as stated in the

manual), and uses all five forward gears.

D4:- This mode is also found in Honda and Acura 4 or 5-speed

automatics and only uses the first 4 gears. According to the manual, it is used

for "stop and go traffic", such as city driving.

D3:- This mode is found in Honda and Acura 4-speed automatics

and only uses the first 3 gears. According to the manual, it is used for stop

& go traffic, such as city driving. This mode is also found in Honda and

Acura 5-speed automatics.

This is the manual selection of gears for automatics, such as

Porsche's Tiptronic. This feature can also be found in Chrysler and General

Motors products such as the Dodge Magnum and Pontiac G6. The driver can shift

up and down at will, by toggling the shift lever (console mounted) like a

semi-automatic transmission. This mode may be engaged either through a

selector/position or by actually changing gear (e.g. tipping the gear-down

paddles mounted near the driver's fingers on the steering wheel).

The predominant form of automatic transmission is

hydraulically operated, using a fluid coupling/ torque converter and a set of

planetary gear-sets to provide a range of torque multiplication.

Parts And Operation:-

A

hydraulic automatic transmission consists of the following parts:

·

Torque Converter/Fluid Coupling

·

Planetary Gear Set

·

Clutch packs & Bands

·

Valve Body

·

Hydraulic or Lubricating Oil

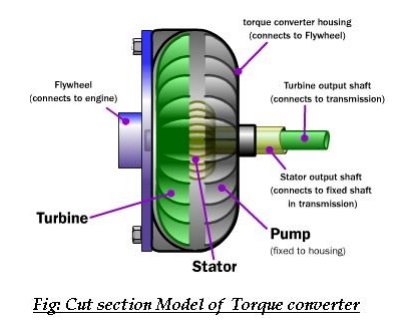

Torque Converter/Fluid Coupling: -Unlike a manual transmission

system, automatic transmission does not use a clutch to disconnect power from

the engine temporarily when shifting gears. Instead, a device called a torque

converter was invented to prevent power from being temporarily disconnected

from the engine and also to pre-vent the vehicle from stalling when the

transmission is in gear.

A fluid coupling/torque converter consists of a sealed chamber

containing two toroidal-shaped, vaned components, the pump and turbine,

immersed in fluid (usually oil). The pump or driving torus (the latter a

General Motors automotive term) is rotated by the prime mover, which is

typically an internal combustion engine or electric motor. The pump's motion

imparts a relatively complex centripetal motion to the fluid. Simplified, this

is a centrifugal force that throws the oil outwards against the coupling's housing,

whose shape forces the flow in the direction of the turbine or driven torus

(the latter also a General Motors term).

Here, Corolis force reaction transfers the angular fluid

momentum outward and across, applying torque to the turbine, thus causing it to

rotate in the same direction as the pump. The fluid leaving the center of the

turbine returns to the pump, where the cycle endlessly repeats. The pump

typically is connected to the flywheel of the engine—in fact,

the coupling's enclosure may be part of the flywheel proper, and thus is turned

by the engine's crankshaft. The turbine is connected to the input shaft of the

transmission. As engine speed increases while the transmission is in gear,

torque is transferred from the engine to the input shaft by the motion of the

fluid, propelling the vehicle. In this regard, the behavior of the fluid

coupling strongly resembles that of a mechanical clutch driving a manual

transmission.

A torque converter differs from a fluid coupling in that it

provides a variable amount of torque multiplication at low engine speeds,

increasing "breakaway" acceleration. This is accomplished with a

third member in the "coupling assembly" known as the stator, and by

altering the shapes of the vanes inside the coupling in such a way as to curve

the fluid's path into the stator. The stator captures the kinetic energy of the

transmission fluid in effect using the left-over force of it to enhance torque

multiplication.

Tiptronic transmission is a special type of automatic

transmission with a computer controlled automatic shift. The driver can switch

the transmission to manual mode, which lets her shift the gear at her wish

sequentially up (+) or down (-) without disengaging the clutch. This works just

like a manual transmission; however, it still uses a torque converter to

transfer power from the engine. Unfortunately, this is less efficient than a

manual transmission.

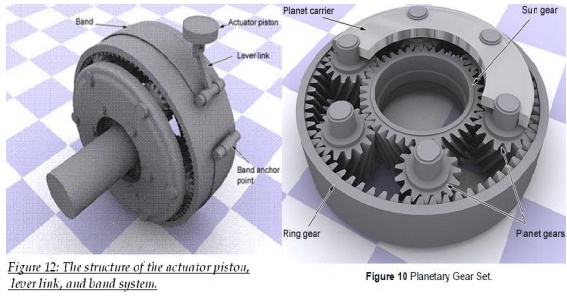

Planetary Gear-Set: - The automatic system for current

automobiles uses a planetary gear set instead of the traditional manual

transmission gear set. The planetary gear set contains four parts: sun gear,

planet gears, planet carrier, and ring gear. Based on this planetary set

design, sun gear, planet carrier, and ring gear spin centrifugally. By locking

one of them, the planetary set can generate three different gear ratios,

including one reverse gear, without engaging and disengaging the gear set. The

gear set is actuated by hydraulic servos controlled by the valve body,

providing two or more gear ratios.

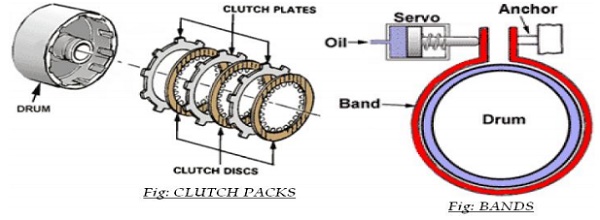

Clutch Packs And Bands: - A clutch pack consists of

alternating disks that fit inside a clutch drum. Half of the disks are steel

and have splines that fit into groves on the inside of the drum.

`The other half have a friction material bonded to their

surface and have splines on the inside edge that fit groves on the outer

surface of the adjoining hub. There is a piston inside the drum that is

activated by oil pressure at the appropriate time to squeeze the clutch pack

together so that the two components become locked and turn as one.

A band is a steel strap with friction material bonded to the

inside surface. One end of the band is anchored against the transmission case

while the other end is connected to a servo. At the appropriate time hydraulic

oil is sent to the servo under pressure to tighten the band around the drum to

stop the drum from turning.

The bands come into play for manually selected gears, such as

low range or reverse, and operate on the planetary drum's circumference. Bands

are not applied when drive/overdrive range is selected, the torque being

transmitted by the sprag clutches instead.

The sun gear is connected to a drum, which can be locked by a

band. The ring gear is directly connected to the input shaft, which transfers

power from the engine. The planet carrier is connected to the output shaft,

which transfers power into the wheels.

Based on this design, when in neutral, both band and clutch

sets are released. Turning the ring gear can only drive planet gears but not

the planet carrier, which stays static if the car is not moving. The planet

gears drive the sun gear to spin freely. In this situation, the input shaft is

not able to transfer power to the output shaft. When shifting to 1st gear, the

band locks the sun gear by locking the drum. The ring gear drives the planet

carrier to spin. In this situation, the ring gear (input shaft) spins faster

than the planet carrier (output shaft).

To shift to higher gear, the band is released and the clutch

is engaged to force the sun gear and planet carrier (output shaft) to spin at

the same speed. The input shaft will also spin at the same speed as the output

shaft, which makes the car run faster than in 1st gear. Using a compound

planetary gear set generates more gear ratios with a special gear ratio,

over-drive gear whose gear ratio is small than 1.

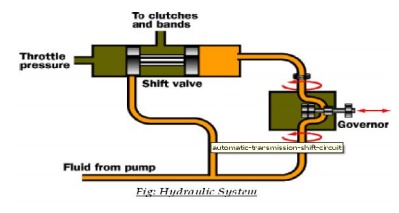

This will make the gear shift smoother. Both the band and

clutch piston are pressurized by the hydraulic system. The part connecting the

band or clutches to the hydraulic system is called the shift valve, while the

one connecting the hydraulic system to the output shaft is called the governor.

The governor is a centrifugal sensor with a spring loaded

valve. The faster the governor spins, the more the valve opens. The more the

valve opens, the more the fluid goes through and the higher the pressure

applied on the shift valve. Therefore, each band and clutch can be pushed to

lock the gear based on a specific spin speed detected by the governor from the

output shaft. To make the hydraulic system work efficiently, a complex maze of

passages was designed to replace a large number of tubes. For modern cars, an

electronic con-trolled (computer controlled) solenoid pack is used to detect

throttle position, vehicle speed, engine speed, engine load, brake pedal

position, etc., and to automatically choose the best gear for a moving vehicle.

Principally, a type of device known as a sprag or roller

clutch is used for routine upshifts/downshifts. Operating much as a ratchet, it

transmits torque only in one direction, freewheeling or "overrunning"

in the other. The advantage of this type of clutch is that it eliminates the

sensitivity of timing a simultaneous clutch release/apply on two planetaries,

simply "taking up" the drivetrain load when actuated,and releasing

automatically when the next gear's sprag clutch assumes the torque transfer.

Valve Body: - Hydraulic control center that receives

pressurized fluid from a main pump operated by the fluid coupling/torque

converter. The pressure coming from this pump is regulated and used to run a

network of spring-loaded valves, check balls and servo pistons.

The valves use the pump pressure and the pressure from a

centrifugal governor on the output side (as well as hydraulic signals from the

range selector valves and the throttle valve or modulator) to control which

ratio is selected on the gearset; as the car and engine change speed, the

difference between the pressures changes, causing different sets of valves to

open and close.

Each of the many valves in the valve body has a specific

purpose and is named for that function. For example the 2-3 shift valves

activate the 2nd gear to 3rd gear up-shift or the 3-2 shift timing valve which

determines when a downshift should occur.

The hydraulic pressure controlled by these valves drives the

various clutch and brake band actuators, thereby controlling the operation of

the planetary gearset to select the optimum gear ratio for the current

operating conditions. However, in many modern automatic transmissions, the

valves are controlled by electro-mechanical servos which are controlled by the

Engine Management System or a separate transmission controller.

The most important valve and the one that you have direct

control over is the manual valve. The manual valve is directly connected to the

gear shift handle and covers and uncovers various passages depending on what

position the gear shift is placed in. When you place the gear shift in Drive,

for instance, the manual valve directs fluid to the clutch pack(s) that

activates 1st gear.

It also sets up to monitor vehicle speed and throttle position

so that it can determine the optimal time and the force for the 1 - 2 shifts.

On computer controlled transmissions, you will also have electrical solenoids

that are mounted in the valve body to direct fluid to the appropriate clutch

packs or bands under computer control to more precisely control shift points.

Hydraulic & Lubricating Oil: - A component called

Automatic Transmission Fluid (ATF) which is part of the transmission mechanism

provides lubrication, corrosion prevention, and a hydraulic medium to convey

mechanical power.

Primarily it is made of refined petroleum and processed to

provide properties that promote smooth power transmission and increase service

life. ATF is one of the parts of the automatic transmission that needs routine

service as the vehicle ages.

Related Topics