Chapter: Mechanical and Electrical : Power Plant Engineering : Steam Power Plants

Ash Handling System

ASH HANDLING SYSTEM:

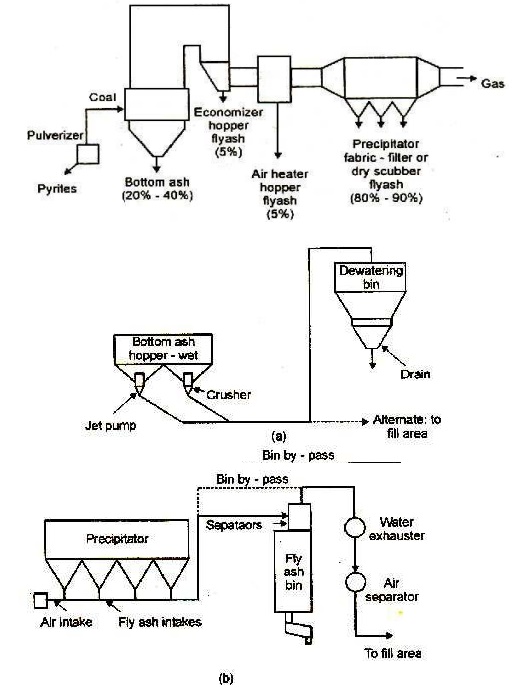

Boilers burning pulverized coal (PC) have bottom furnaces. The large ash particles are collected under the furnace in a water-filled ash hopper, Fly ash is collected in dust collectors with either an electrostatic precipitator or a baghouse. A PC boiler generates approximately 80% fly ash and 20% bottom ash. Ash must be collected and transported from various points of the plants as shown in figure. Pyrites, which are the rejects from the pulverizers, are disposed of with the bottom ash system. Three major factors should be considered for ash disposal systems.

1. Plant site

2. Fuel source

3. Environmental regulation

Needs for water and land are important considerations for many ash handling systems. Ash quantities to be disposed of depend on the king of fuel source. Ash storage and disposal sites are guided by environmental regulations.

1 Ash Handling Equipment:

Mechanical means are required for the disposal of ash. The handling equipment should perform the following functions: 1. Capital investment, operating and maintenance charges of the equipment should be low. 2. It should be able to handle large quantities of ash. 3. Clinkers, shoot, dust etc. create troubles.The equipment should be able to handle them smoothly.4. The equipment used should remove the ash from the furnace, load it to the conveying system to deliver the ash to dumping site or storage and finally it should have means to dispose of the stored ash. 5. The equipment should be corrosion and wear resistant.

Hydraulic System

In this system, ash from the furnace grate falls into a system of water possessing high velocity and is carried to the sumps. It is generally used in large power plants. Hydraulic system is of two types, namely, low pressure hydraulic system used for intermittent ash disposal figure. Figure shows hydraulic system.

Water-Jetting System

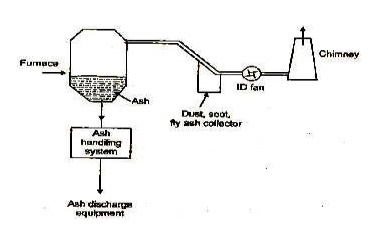

Water jetting of ash is shown in figure. In this method a low pressure jet of water coming out of quenching nozzle is used to cool the ash. The ash falls into trough and is then removed.

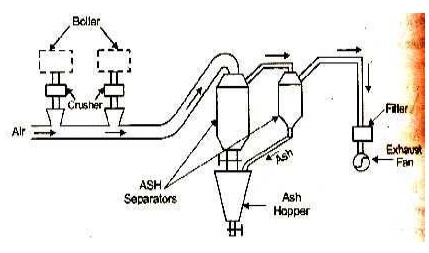

Pneumatic System

In this system ash from the boiler furnace outlet falls into a crusher where a lager ash particles are crushed to small sizes. The ash is then carried by a high velocity air or steam to the point of delivery. Air leaving the ash separator is passed through filter to remove dust etc. So that the exhauster handles clean air which will protect the blades of the exhauster.

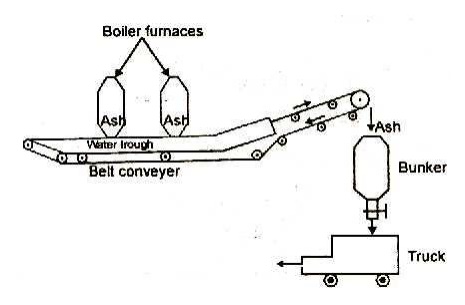

Mechanical system

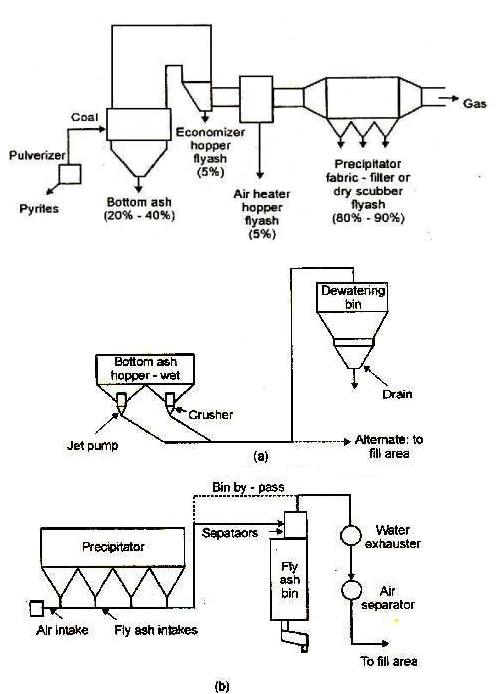

Figure shows a mechanical ash handling system.

In this system ash cooled by water seal falls on the belt conveyor and is carried out continuously to the bunker.

Related Topics