Chapter: Aquaculture Engineering : Sea Cages

Anchors - Mooring systems

Anchors

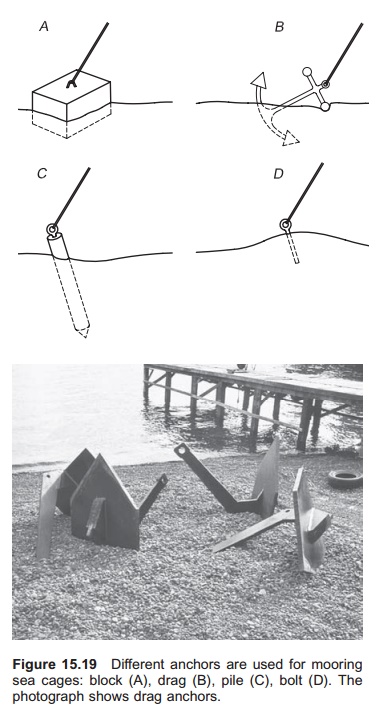

The simplest type of anchor is the dead weight or block anchor. Theoretically all heavy objects, such as old engines may be used, but they may be difficult to handle. In addition, this may result in chafing of the mooring lines. Concrete blocks are most commonly used as weight anchors and vary from some hundreds of kilograms to several tonnes. As the density of concrete is quite high (around 2.4 t/m3) it will easily sink to the bottom, stay there and take up forces. The great disadvantage with block anchors is that they are heavy to handle. Large cranes are needed on the boats setting them out and precautions must be taken to avoid tilting the boat during this operation.

To prevent block anchors being displaced on the bottom, good friction between anchor and the bottom is necessary; this depends on the bottom conditions and is given by the friction coefficient. Sand and clay have high friction coefficients while that of rock is low (between 0.1 and 0.5), meaning that an anchor will slide easily on rock. Block anchors are not recommended for use on rocky ground; here either drag anchors or bolts should be used. Friction coefficients of 0.5 for sand and 0.3 for clay may be used as a basis, for anchor choice if no measurements are done.

To increase the friction coefficient, the bottom of the anchors can be rough, even having iron bars emerging from the base. Another method of increasing the friction is to add an iron jacket around the bottom of the block. This will increase the forces holding the anchor on the bottom, because it is sucked to the bottom like a sucking disc, assuming suitable ground conditions such as clay. The angle at which the mooring line is joined to the block is, of course, also important in inhibiting horizontal movement. To avoid tilting of block anchors, the width of the blocks ought to be large in relation to the height (>2 : 1), or the block anchor may tilt over the mooring lines and cause chafing.

A drag anchor or ebbing anchor is another type much used (Fig. 15.19). The aim of the design is for the anchor to be dragged down into the ground like a plough and become fixed. Various designs of ebbing anchors are available, and the different suppliers normally have their own designs. The old traditional one is the stock anchor as used on boats; today more effective designs for mooring of fish farms are available. How well fixed an ebbing anchor is to the bottom depends on the bottom conditions and the design of the anchor; the angle of the mooring line is also important. The optimum angle depends both on the bottom conditions and anchor design. The angle for ebbing anchors used in sand can be 30–35° and in clay 30–50°.

An ebbing anchor will tolerate a large horizon-tal force, but tolerance of vertical forces is low. To improve this, a heavy chain may be used before the anchor. Another method is to use a small block weight on the mooring line before the anchor. An ebbing anchor is of much lower weight than a block anchor, because it is based on a totally different principle, but is more expensive. From the back edge of the ebbing anchor there should be a rope to the surface; to keep the rope on the surface where it can be reached, it is attached to a buoy. This must be done to ensure the anchor can be released when removal is necessary, otherwise this might be impossible as the anchor is normally

Bolts can be used to advantage where it is possible to fasten the mooring lines in rock, usually where the mooring lines lead to land, but bolts mayalso be use under the water surface. Galvanized bolts are set into drilled holes; either they can have an expanding construction or expanding slurry canbe injected into the holes. The bolts are either of the eye or T-type.

Piles are an alternative in sand and clay bottoms, but the forces they can take up are normally quite low; otherwise they must be very large which increases the cost considerably.

There are several other special anchors that could be used, but they are normally more expensive. One type used in the offshore oil industry is the suck anchor. In principle the anchor is a large specially designed sucking cup that sucks down to the bottom. This can be made from a wire-spoked wheel with a plastic cover.

Related Topics